If you ever ask yourself how the metal or plastic parts that look so perfect are made, CNC machining is the answer. CNC multi-axis machining has evolved into the worldwide manufacturers’ preferred choice to meet the tightening of tolerance and complexity of design requirements of the industry.

However, the main question remains: Should one go for 3-axis, 4-axis, or 5-axis CNC machining? We will help you figure out what works best for your project by breaking down the options in simple terms without any unnecessary details.

What Is CNC Multi-Axis Machining?

CNC multi-axis machining means a CNC machine that can move a cutting tool or a workpiece in various directions at the same time. Generally, if the machine has more axes, it can produce more complex figures with fewer setups.

In layman’s words:

- More axes = more flexibility

- More flexibility = better precision and productivity

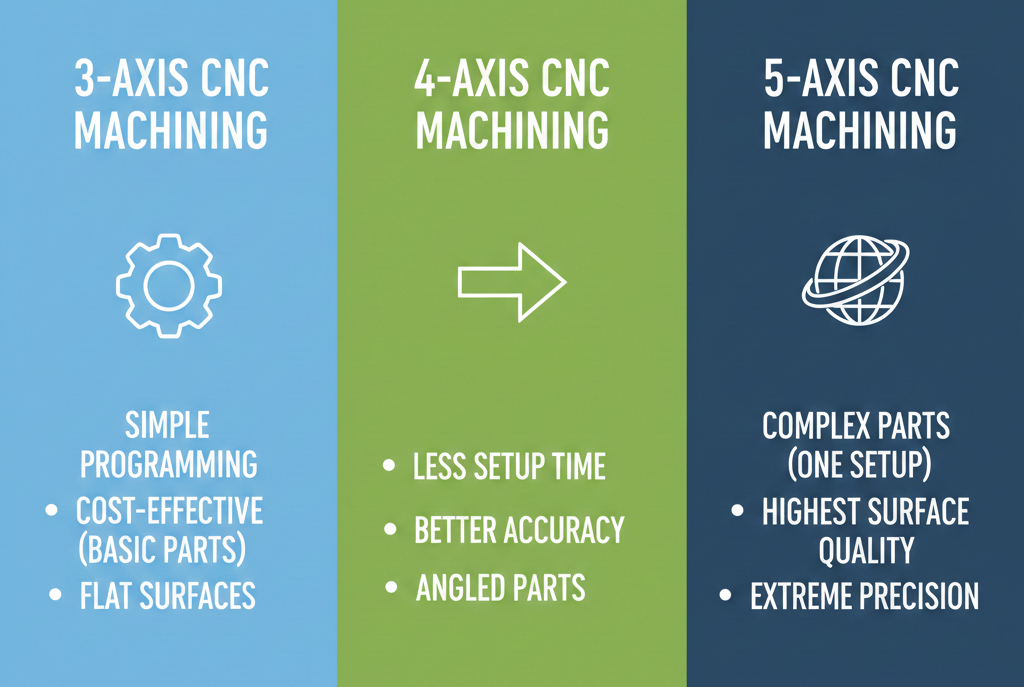

3-Axis CNC Machining

The classic choice, 3-axis CNC machining, is the most popular and common type of technology. It works along three linear axes:

- X-axis (left to right)

- Y-axis (front to back)

- Z-axis (up and down)

What are the advantages of 3-axis machining?

- Programming is simple, and the machine is easy to operate

- It is cost-effective for the production of basic parts

- Works well with flat surfaces and geometries that are easy to understand

Drawbacks to consider

- You may have to do several setups

- It cannot be used to produce complex or curved parts

In brief, 3-axis machining is very good for simple designs when the budget is a more important factor than the complexity of the design.

4-Axis CNC Machining: One Step Further

4-axis CNC machining adds a rotational axis (usually called the A-axis). In this way, the workpiece rotates, making it easier to machine multiple sides without repositioning.

Key advantages

- It requires less time for the setup

- Gives better accuracy as compared to 3-axis

- Nice choice for the production of cylindrical or angled parts

Where it shines

- Automotive components

- Shafts, gears, and brackets

This is how multi-axis machining can actually demonstrate its power by delivering consistency while saving time.

5-Axis CNC Machining: Maximum Precision & Freedom

5-axis CNC machining is the most sophisticated type of CNC machining available at this time. It features two additional rotational axes to the machine tool, which allows the tool to reach the part from practically any angle.

The reason why manufacturers pick 5-axis machining

- Complex parts can be created in one setup

- Surface finish of the highest quality

- Extremely high precision level

Common applications

- Aerospace parts

- Medical implants

- High-end automotive and defense parts

In spite of the fact that 5-axis machining costs more, it is often justified by intricately designed, expensive components. This is the best example of multi-axis CNC machining at its fullest.

Quick Comparison Table

| Feature | 3-Axis | 4-Axis | 5-Axis |

|---|---|---|---|

| Axes of Movement | 3 | 4 | 5 |

| Complexity Handling | Low | Medium | High |

| Setup Time | High | Medium | Low |

| Cost | Low | Medium | High |

| Precision Level | Standard | Improved | Very High |

Which One Should You Choose?

Choosing the right machining method is largely influenced by four factors:

- Part complexity – The number of curves and angles determines the number of axes

- Production volume – More production means less time is required for set-ups

- Budget – High-end machines may be more expensive, but they are time-saving

- Tolerance requirements – Slightly higher precision may be the reason for the higher cost

Multi-axis CNC machining is the method of choice for many manufacturers as it offers the necessary flexibility without sacrificing quality.

Why Multi-Axis Machining Is Still Relevant

Speed, precision, and consistency are the main requirements of modern industries. Tighter deadlines and more complex designs make the use of traditional methods unfeasible.

CNC multi-axis machining can achieve these goals by:

- Eliminating human error

- Enhancing repeatability

- Shortening the lead time for complicated parts

At Mechman Solution, we know how crucial it is to pick the perfect machining technique for your job-the right decision will result in both time and money savings.

Final Thoughts

It basically depends on what kind of project you have (its needs, budget, and complexity), whether you choose 3, 4, or 5-axis CNC machining. However, 3-axis machining is still a cheap way to make your simple parts, and for that, it is a reliable solution. The use of 4-axis machining in the production process helps to fold the operations and therefore to make the work more efficient in a more detailed component. If you can’t do without great precision, accuracy, and intricate shapes, then 5-axis machining is the one to choose.

Knowing these differences will help you make better manufacturing decisions and give you the opportunity to use the CNC multi-axis machining advantages fully, which include faster production, improved quality, and long-term success.

FAQs

1. Is 5-axis CNC machining always better than 3-axis?

Not all the time. 5-axis has more capabilities, but it is also more expensive. Usually, 3-axis machining is the best option when you have simple parts.

2. Does multi-axis machining shorten the production time?

Definitely. Part repositioning is minimized in multi-axis CNC machining, thus the machining and setup time is greatly reduced.

3. Which industries make more use of 5-axis machining?

The industries that most benefit from it are aerospace, medical, automotive, and defense as they require high precision and complex geometries.

Contact Us

📞 +91 99137 89065