Surface finish is super important in making things precisely. It’s not just about looks; a smooth surface helps parts work better, resist wear, and fit together correctly. The way you program your machines with CAM software can really make a difference in getting that nice finish. Let’s see how you can get a better surface finish using the right CAM machining strategies without wasting time.

What Surface Finish Really Means

Surface finish is basically how a part feels and looks after it’s been machined. You can measure it by how rough it is, how wavy it is, and what kind of pattern the machining leaves. Even small things like changing the toolpath, how fast the tool moves, or the cutting method can totally change the final result. If you get these things right, you can really control how your parts turn out.

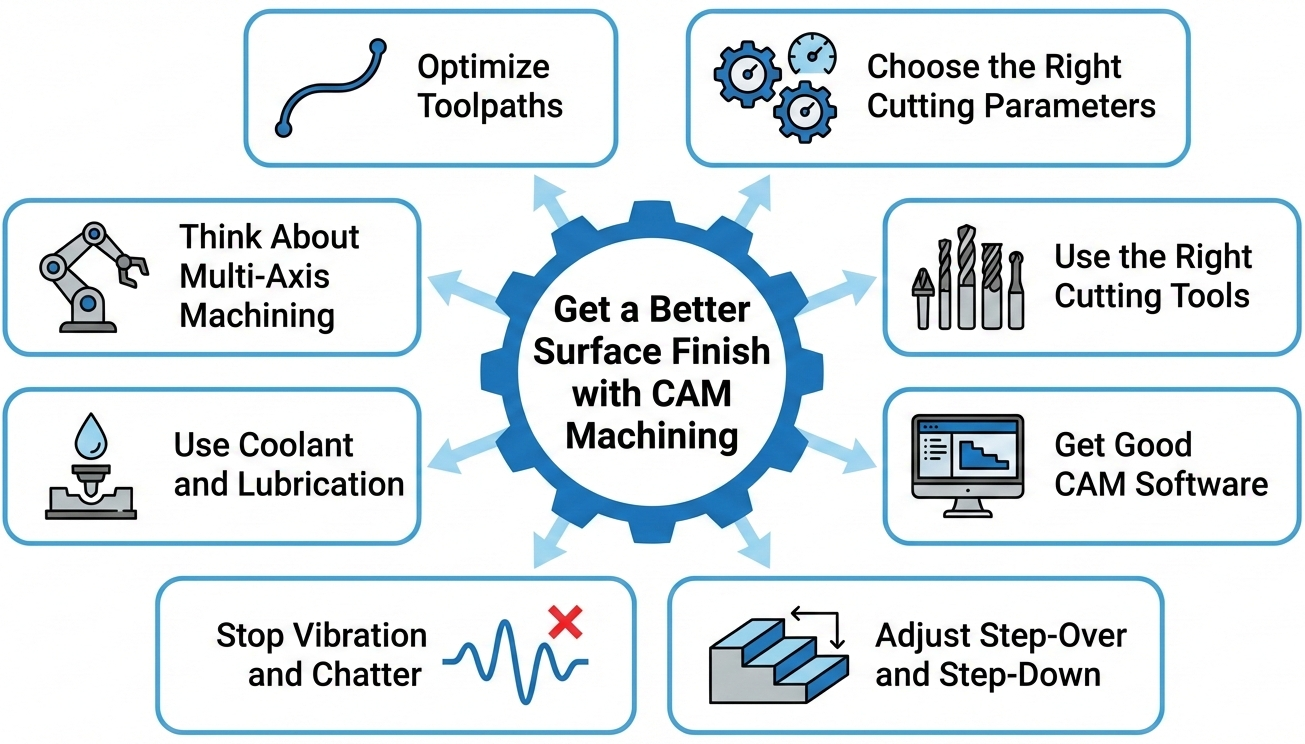

How to Get a Better Surface Finish with CAM Machining Strategies

1. Optimize Toolpaths

The right path will leave fewer marks and cause less vibration.

- Climb Milling vs. Conventional Milling: Climb milling usually gives a smoother finish because it stops the tool from bending as much.

- Adaptive Toolpaths: Lots of newer CAM programs have adaptive clearing, which keeps the amount of material the tool removes consistent. This means fewer bumps and dips on the surface.

- Finishing Passes: Always do a separate finishing pass. Don’t try to get your final finish with the same toolpath you used for roughing.

2. Choose the Right Cutting Parameters

Even the coolest CAM strategies won’t work if your cutting settings are off.

- Spindle Speed and Feed Rate: Usually, speeding up the spindle and slowing down how fast the tool moves through the material will give you a better finish.

- Depth of Cut: When you’re doing the finish, take off less material each time. This keeps the tool from pushing too hard and messing up the surface.

- Tool Engagement: Try not to let the tool suddenly dig into the material. This can cause vibrations and uneven surfaces.

3. Use the Right Cutting Tools

What tool you use is just as important as how you use it.

- Tool Material: Carbide tools are great for finishing at high speeds. HSS tools are okay if you’re cutting slower.

- Tool Shape: A tool with a bigger curve on the tip or polished edges will leave a much smoother surface.

- Tool Condition: Always check your tools for wear. Worn-out tools will give you a bad surface finish, no matter what CAM strategy you use.

4. Get Good CAM Software

New CAM software has cool features that can help with surface finish.

- Spline and Curve-Based Toolpaths: These make the tool change direction smoothly.

- Simulation and Verification: This helps you see if the tool will cut too deep or not enough before you actually machine the part.

- Fine-Tuning Tools: Some programs can change how far the tool steps over, how fast it moves, and how fast the spindle turns to get the best finish.

5. Adjust Step-Over and Step-Down

Step-over is how far the tool moves to the side between passes. Step-down is how far it moves down. These settings really change the surface texture.

- Smaller step-over = smoother surface, but it takes longer

- Smaller step-down = better finish in deep spots and tricky shapes

Below is a quick reference table for finish pass recommendations:

| Parameter | Recommendation for Better Finish |

|---|---|

| Step-over | 10–20% of the tool diameter |

| Step-down | 0.5–2 mm depending on material |

| Spindle speed | Higher than roughing speed |

| Feed rate | Lower than roughing feed |

6. Stop Vibration and Chatter

Vibration is bad for surface finish. Even if your CAM program is perfect, the machine can ruin the finish if it’s shaking.

- Use shorter, stronger tools

- Make sure the part is clamped down tight

- Don’t let the tool stick out too far

- Avoid big changes in how the tool is cutting

7. Use Coolant and Lubrication

Using coolant the right way can make the surface better.

- Keeps the tool and part cool, so they don’t expand

- Washes away chips, so they don’t scratch the surface

- Makes the tool last longer

8. Think About Multi-Axis Machining

If you’re working with complicated surfaces, using a 5-axis machine can help. You can point the tool in the best direction, which means fewer crashes and a nicer surface in fewer passes.

By using these CAM machining strategies, you can really improve your surface finish, cut down on extra work, and make your parts perform better. Getting a smooth surface is all about using smart toolpaths, the right settings, and good tools, plus a little patience.

FAQs

1: Can CAM strategies alone guarantee a perfect surface finish?

No. While CAM machining strategies play a big part, the tools you pick, how strong the machine is, and what material you’re using all matter.

2: How often should I adjust step-over and step-down for finishing?

It depends on the material and the shape. For most metals, a 10–20% step-over and small step-downs work well. You really need to test it out.

3: Does higher spindle speed always improve surface finish?

Not always. Usually, it helps, but you have to balance it with how fast the tool moves and how good the tool is. If it’s too high, it can cause vibrations and heat problems.

Contact Us!

📞 +91 99137 89065