If you’re getting started with CNC machining, you’ve probably heard about something called a CNC post-processor. What is it? Why is it something important for today’s manufacturing? It takes what your CAD/CAM software creates and turns it into something your CNC machine can understand. Without it, your machine wouldn’t be able to make any parts you have designed.

Let’s make this easier to understand.

What is a CNC Post Processor?

A CNC post-processor is a piece of software that changes the toolpaths from your CAM (Computer-Aided Manufacturing) software into the special G-code that your CNC machine needs. Every CNC machine speaks a slightly different language, so the post-processor makes sure that everything is compatible.

Here is another way to think about it: Your CAM software speaks CAM language. Your CNC machine only understands machine language. The post-processor translates the two languages to make sure they communicate well.

Here are some important points about CNC Post Processors:

- Machine-Specific Output: Every machine, even from the same brand, requires a specific G-code. The post-processor takes care of these unique needs.

- Less Chance of Mistakes: When you use the correct post-processor, this reduces mistakes during machining, which can save time and money.

- Efficiency: The post-processor makes smooth G-code that helps your machine run well without any weird movements.

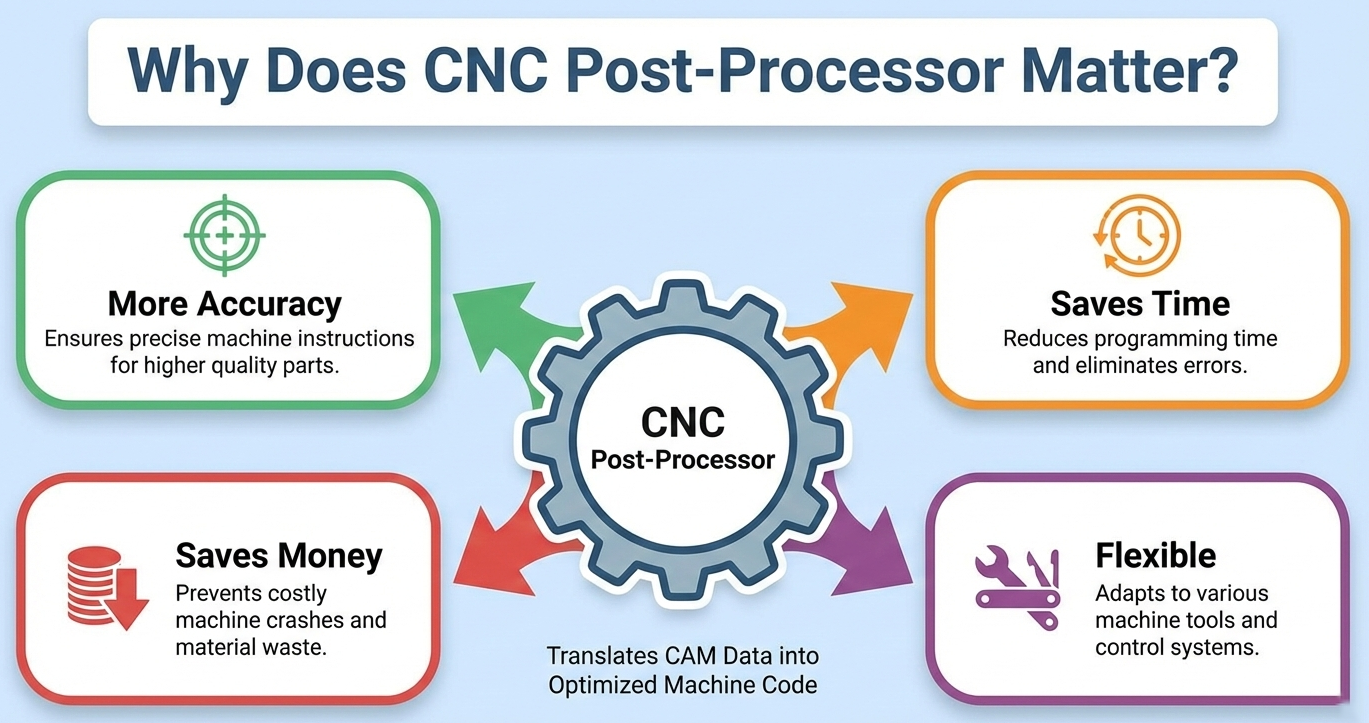

Why Does It Matter?

A CNC post-processor is very important, and here’s why:

- More Accuracy: Even a small difference in the G-code can make a big mess. A good post-processor makes very specific code for your machine.

- Saves Time: It takes a long time to manually change the code for your machine. A post-processor does it automatically.

- Saves Money: When you reduce errors, you waste less material. You will also extend your machine’s life by reducing machine wear.

- Flexible: If you work with different machines, a post-processor makes sure you will have uniform results.

How It Works

Here’s the simple version:

- Design with CAD: First, the part is designed by you in CAD.

- Make a Toolpath in CAM: The CAM software will tell the machine how fast to cut and the specific path to use.

- Post Processing: Then, the post-processor translates that pathed cutting into the specific G-code that your CNC machine can follow.

- CNC Machine: Now you load the G-code into the CNC machine, and it cuts the part exactly how you designed it.

It sounds simple, but if you use the wrong post-processor, you could have problems like these:

- The tool could collide with something.

- The machine might cut too fast or too slow.

- The spindle might spin at the wrong speed.

- You could waste material.

The post-processor is something you must have and is essential.

Different Types of CNC Post Processors

There are different types, depending on what machine and software you use:

| Type | Description |

|---|---|

| Generic Post Processor | It may work for most machines, but it needs someone to tweak it manually. |

| Machine-Specific Post Processor | Made just for one machine model, it works much better. |

| Custom Post Processor | If you have special needs, then you can have one made just for you. |

A custom post-processor provides the best outcome, mostly for complex or high-accuracy projects.

Common Mistakes That Should Be Avoided

Even the really experienced machinists make mistakes. These can be avoided if caution is taken:

- Using a basic post-processor without making any changes.

- Not knowing the limits of the machine. This includes limits for the axes or rotary table.

- Not paying attention to how the tools change and the offsets in the post-processor settings.

If you pay attention, you will have money and time. On top of that, you can also avoid a lot of headaches.

To Sum It Up

The CNC post-processor is the connection between your designs and the real world. If you are a novice or an expert, you can have success with a post-processor. With this, you will have more correctness, run more smoothly, and improve output in your workshops.

Investing in a post-processor will produce better parts. It will also reduce errors and smooth operations. This is a behind-the-scenes tool that will contribute to manufacturing success.

FAQs

1. Can I use the same post-processor for multiple CNC machines?

This is possible if you use a generic post-processor. However, you may have to make manual changes.

2. How often should the CNC post-processor be updated?

When the CAM software updates or the machine has an upgrade, you should check for updates.

3. Do I have to have a special post-processor for simple machining?

If it’s basic, then the generic or machine-specific post-processor should be appropriate. However, you should use custom versions when things become highly specialized.

Contact Us!

📞 +91 99137 89065