If you’re regularly cutting metal with CNC machines, you probably know a secret: even the fanciest CAM software can’t promise perfect parts all the time. The real magic happens when you change those CAM designs into code that the machine can read. Let’s discuss when you need to switch to a custom post-processor CNC. It can be a very big change to your CNC process.

What Exactly Is a Custom Post-Processor

Think of it like this: A post-processor translates the paths your CAM software designs into G-code that your CNC machine could understand. A custom post-processor CNC is built to fit:

- The exact type of machine you are using

- The controller that runs it (such as Fanuc, Siemens, or Haas)

- How your machine shop works

With an old method, everyone is trying to adapt to generic code. In the newer method, the code is changed to work with the machine, and that makes a huge impact.

When Should You Get a Custom Post-Processor

If you’re just getting started, you might not need a custom post-processor right away.

Think about getting a custom one if:

- Your machine moves in special ways (maybe it’s a 5-axis, mill-turn, or Swiss-type machine).

- You use cycles or macros that do jobs automatically.

- You are usually changing the G-code by hand.

- Your parts must be nearly perfect every time.

- You have lots of machines that use different controllers.

Do any of these points sound like your situation? If so, you may want to upgrade from the standard post-processors.

Why Standard Post-Processors Fall Short

Standard post-processors are created to work with as many machines as possible. That means they can’t be perfect for any of them.

Here are a few problems you might see:

- The code has too many or too few lines.

- The commands to change tools are wrong.

- The way the machine spins parts isn’t right.

- The code doesn’t include safety moves.

- The speeds and feeds aren’t set as efficiently as possible.

All these little things can waste time, ruin parts, and upset the people working with the machines.

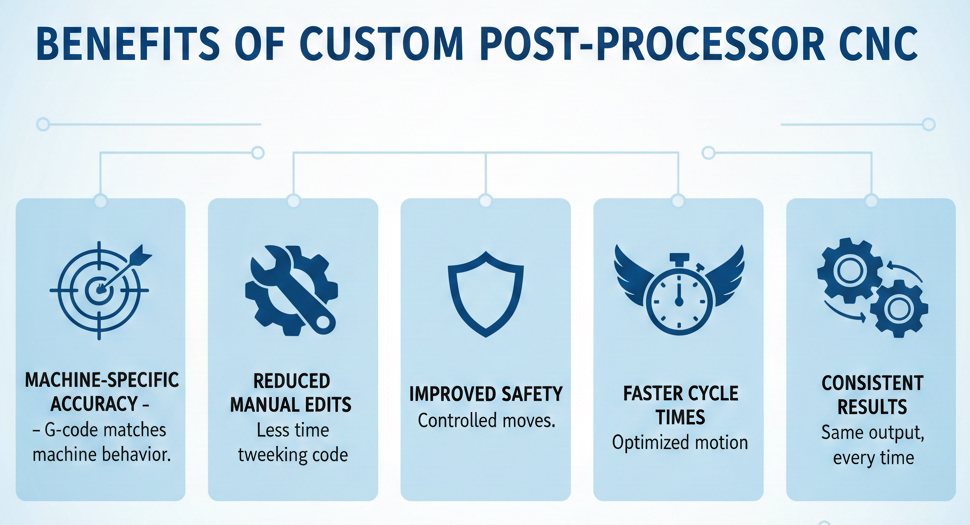

Benefits of Using a Custom Post-Processor CNC

Getting a custom solution won’t just make the code look nicer; it will also improve the overall process.

The main benefits are:

- The machine will be more accurate because the G-code is made to match your specific machine.

- You won’t have to change the code as much by hand, which means less time spent fixing things on the shop floor.

- The machine will be safer because the custom code can control how it approaches, pulls away from, and moves around parts.

- The machine can finish jobs more quickly because the motion is as good as it can be, and there are fewer unnecessary commands.

- You’ll get the same results every time, no matter who is operating the machine.

Basically, a custom post-processor CNC helps your machines work the way they should have from the start.

Standard vs Custom Post-Processor: A Quick Comparison

Here is a comparison between the two types of post-processors:

| Feature | Standard Post-Processor | Custom Post-Processor |

|---|---|---|

| Machine matching | Fits many machines | Made for one machine |

| Code optimization | Limited | Fully optimized |

| Manual editing | Usually needed | Only a little or not at all |

| Advanced cycles | Basic supported | Fully supported |

| Long-term efficiency | Average | High |

In Conclusion

At the end, CNC machines depend heavily on the correctness of the code that they follow. Using standard solutions could give you a result in a few days, but expansion will require more intelligent tools. A custom post-processor CNC is a device that connects your CAM software to the actual machine, providing more efficient code, safer machine conditions, and greater output. It will be hard for you to understand why you hadn’t made the decision to change earlier, when everything will operate more smoothly with your machines and your staff will be less occupied with code fixes.

FAQs

1. Will it cost too much to get a CNC Processor?

It might take some money to buy this, but errors will go down, time won’t be wasted, and the code will be set up automatically.

2. Can one custom post-processor work for multiple machines?

Sometimes, but the final answer is that each machine-controller combination should have its own post for the best results.

3. Do I need a custom post-processor for three-axis machines?

It isn’t always necessary. However, if consistency and accuracy are critical, then even three-axis machines can be beneficial from custom solutions and solve the problem appropriately.

Contact Us!

📞 +91 99137 89065