In today’s rapidly changing manufacturing industry, small and medium-sized enterprises (SMEs) often feel pressured to keep up with larger companies that have far more money and people. Luckily, modern tech is evening things out with tools like CAD/CAM software. CAD/CAM for SMEs gives smaller manufacturers the ability to design, test, and make things with the same level of accuracy that used to be only for big companies.

Accuracy and Cost Savings

Using computer-aided design (CAD) and computer-aided manufacturing (CAM), even a small shop can produce detailed designs, improve production, and reduce mistakes. This means faster completion times and the ability to take on work that seemed impossible before.

One of the best things about using CAD/CAM for SMEs is that it makes things more accurate. Old-fashioned ways usually involve a lot of hand calculations, drawings, and trial-and-error. With CAD/CAM, you can copy designs, test them on a computer, and change things before using any materials. This saves time and reduces costs, which is excellent for SMEs with limited funds.

Customization and Niche Opportunities

CAD/CAM for SMEs is also great for making things that people want. Small manufacturers can now sell highly customized products without significantly increasing production costs. Whether it’s parts for machines, specialized products for people, or detailed metalwork, CAD/CAM software enables accuracy. This ability to sell to smaller groups gives SMEs an advantage that large manufacturers find hard to match, as they focus on making many of the same products.

Bringing CAD and CAM together makes collaboration easier. Designers, engineers, and shop-floor workers can all view the same design on a computer, so everyone knows what’s going on. This cuts down on misunderstandings and speeds up the process of making things. A small team can now work as effectively as a larger company, enabling SMEs to change and meet client needs faster.

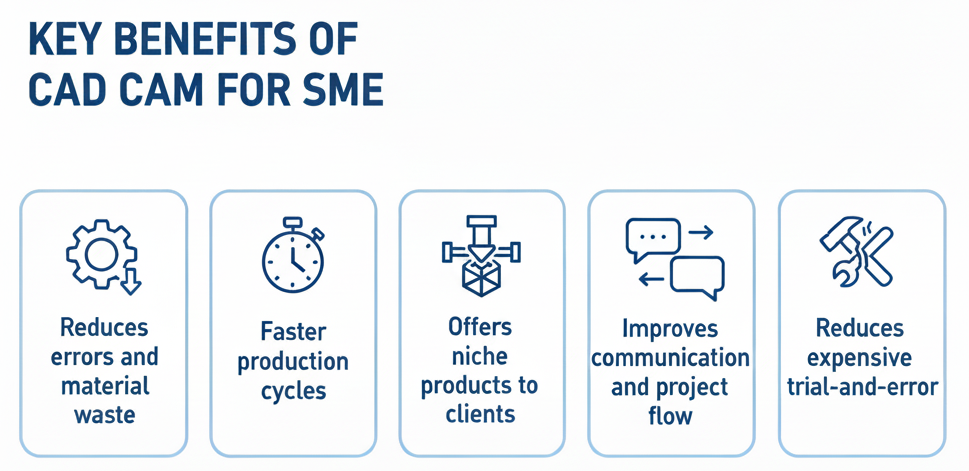

Here’s a table showing some main benefits of CAD CAM for small manufacturers:

| Feature | Benefit for SMEs |

|---|---|

| Design Simulation | Reduces errors and material wastage |

| Automated Manufacturing | Faster making times |

| Customization Capabilities | Offers niche products to clients |

| Collaboration Tools | Improves communication and project flow |

| Cost Efficiency | Minimizes expensive trial-and-error |

Overcoming Challenges

Although there are many benefits, some SMEs worry that CAD/CAM software might cost too much or be hard to get started. The good news is that CAD/CAM programs are becoming easier to use and can be customized to meet different needs. Many options let small manufacturers start with simple things and add more as needed. This means even small shops can use tech to make things without spending a lot of money upfront.

Training is something else to think about. CAD/CAM software does take some learning, but it pays off a lot. Workers can learn to use design tools quickly, copy production, and control machines accurately. Over time, this makes workers better skilled, which helps the company.

Encouraging Innovation

CAD CAM’s ability to change also lets SMEs try new ideas. Because designs can be changed and tested on a computer quickly, manufacturers can try new ideas without worrying about wasting money. This makes people more creative and keeps improving things, which is important for staying ahead in today’s business.

Also, adding CAD/CAM can open doors to new work opportunities. Companies can get clients who want high-quality, accurate making without the cost of working with a big company. SMEs that invest in CAD/CAM can outperform expectations, selling products that are as good as those from larger companies.

Conclusion

In short, using CAD/CAM software is now a smart business move for small manufacturers. It makes things accurate and effective while keeping costs under control. By using this tech, SMEs can compete with confidence, reach niche markets, and sell high-quality products quickly. In a business where being able to change and being good at things often decide who wins, CAD/CAM for SMEs can really change the game.

FAQs

1. Is CAD/CAM software too costly for small manufacturers?

Not always. There are options for SMEs that let you start small and add features as your business grows.

2. How long does it take to learn how to use CAD/CAM software?

You can learn basic things in a few weeks, while more complex things might take a few months. Many software companies offer training and help SMEs learn quickly.

3. Can CAD/CAM really make production better?

Yes. By reducing mistakes, automating processes, and allowing testing on a computer, CAD/CAM software greatly improves efficiency and lowers costs for small manufacturers.

Contact Us

📞 +91 99137 89065