In the rapidly evolving manufacturing industry, the importance of time is emphasized to such an extent that it seems that every second counts on the shop floor. Regardless of whether you are operating a small CNC setup or overseeing a large-scale production facility, the need to provide results faster while maintaining quality is still there. One of the cleverest measures taken to reduce CNC cycle time is by using modern CAM software.

Understanding CNC Cycle Time

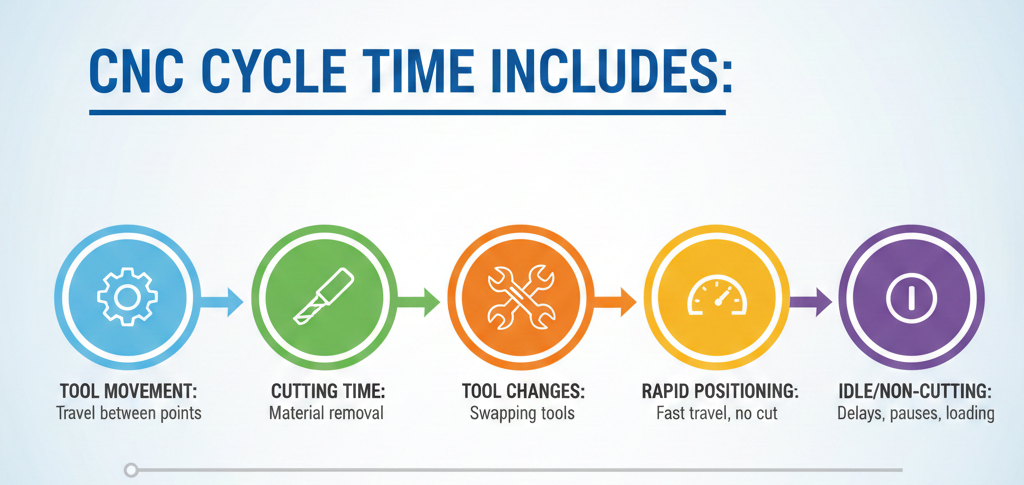

Before we talk about CAM, it is appropriate to understand what CNC cycle time means. CNC cycle time refers to the total time a machine takes to make one part; it is the time from the beginning until the end of the process. This includes:

- Tool movement

- Cutting time

- Tool changes

- Rapid positioning

- Idle or non-cutting motions

That means only a small improvement in one of these areas can lead to time savings on an enormous scale, involving hundreds or thousands of parts.

What Makes CAM Software So Important?

Manual programming or using old CAM systems can bring inefficiencies without an end, because those systems are not capable of attaining high levels of optimization. With modern CAM software, intelligent algorithms are employed in order to make the machining process as efficient as possible.

Here is what it does practically and measurably in order to reduce CNC cycle time.

Smarter Toolpath Optimization

One of the largest benefits of using CAM software is optimized toolpaths.

Rather than inefficient zigzags or air cuts, CAM software determines the shortest, most efficient cutting paths. This is what it stands for:

- Less non-cutting movement

- Smoother transitions between operations

- Lowered machine wear

The result? The machining is done faster, but the machine is not pushed too hard.

High-Speed Machining Strategies

Today’s CAM software is capable of implementing high-speed machining (HSM) techniques. These methods allow the cutting tool to keep constant engagement with the material.

Benefits are:

- Higher feed rates

- Lower tool load

- Improved surface finish

When the tool is smoothly engaged, machines can operate at higher speeds and with less risk of damage, which is yet another efficient method to shorten the CNC cycle time.

Fewer Tool Changes, More Productivity

Each tool change is responsible for adding extra seconds, and those seconds in a heap add up quickly.

CAM software helps by:

- Operations using the same tool are combined

- Optimum tools for several features are selected

- Unnecessary tool changes are reduced

This little adjustment in the work process often results in noticeable time savings during long production runs.

Simulation Helps Avoid Costly Mistakes

Machine crashes and errors are not only expensive but also time-consuming.

CAM software comes with a real-time simulation that enables you to:

- Detect collisions before machining

- Confirm toolpaths visually

- Remove trial and error from the shop floor

By doing it right the first time, you are free to run jobs at a higher speed and thus save on downtime.

Automated Features Save Programming Time

CAM software is not only a great tool for quickly machining, but also for quickly programming.

Some good automation features that your programming work will benefit from are:

- Feature-based machining

- Automatic roughing and finishing

- Template-based operations

Lower programming time leads to faster job setup and quicker production starts, which is a great way for shops to reduce CNC cycle time.

A Simple Comparison Table

Here’s a simple comparison table on how CAM software improves cycle time in comparison to traditional methods:

| Aspect | Without CAM Software | With CAM Software |

|---|---|---|

| Toolpath efficiency | Manual & inconsistent | Optimized & automated |

| Programming time | High | Low |

| Machine idle time | Frequent | Minimal |

| Error detection | On machine | Before machining |

| Overall cycle time | Longer | Shorter |

Better Machine Utilization

With the help of CAM software, machines are kept near their optimal capacity. Machines in such a scenario are more cutting efficient and have less waiting time by balancing speed, tool life, and cutting efficiency. The thing that is being done here is to reduce CNC cycle time and the overall productivity and ROI of the shop to be improved as well.

CAM software guarantees:

- Repeatable machining processes

- Standardized toolpaths

- Predictable cycle times

Planning production schedules and delivering parts on time becomes much easier with this. To cut down on CNC cycle time without compromising on quality or safety, CAM software is arguably the most effective tool.

FAQs

1. Is the reduction of CNC machine time using CAM technology really as big as stated?

Yes. Many shops have achieved such goals by means of optimized toolpaths, error reductions, and high-speed machining strategies.

2. Is CAM software suitable for small machine shops?

Certainly, even micro shops get a long programming time, better efficiency, and repeatability of results.

3. Does reducing cycle time affect part quality?

No. When done correctly with CAM software, cycle time reduction improves surface finish and dimensional accuracy.

Contact Us

📞 +91 99137 89065