The CNC industry is undergoing a rapid transformation, and it’s truly exciting to witness. Processes that once relied heavily on manual procedures, paper-based designs, and iterative machining are now becoming smarter, faster, and more interconnected. Central to this evolution is digital manufacturing – a transformative paradigm that is reshaping how modern CNC workshops operate.

For CNC shops aiming to maintain a competitive edge, curb waste, and ensure better quality, embracing digital tools is now a necessity.

What Exactly Is Digital Manufacturing in CNC

In simple terms, digital manufacturing integrates design, simulation, machining, and inspection through digital tech. Instead of handling each stage separately, everything is synchronized in a seamless digital flow.

This encompasses:

- CAD/CAM integration

- Digital twins and simulations

- Intelligent CNC machines equipped with sensors

- Real-time production monitoring

By using digitally integrated manufacturing, CNC workshops can make more informed decisions before any material is even cut.

Why CNC Workshops Are Going Digital

Traditional CNC setups still work, but they have limitations – longer setup times, higher scrap rates, and delayed feedback. Digital manufacturing addresses many of these concerns.

Here’s what is fueling this shift:

- Quicker production planning

- Reduced material waste

- Improved accuracy and consistency

- Better machine use

- Real-time performance insights

Workshops that adopt it often see increased productivity without needing more staff.

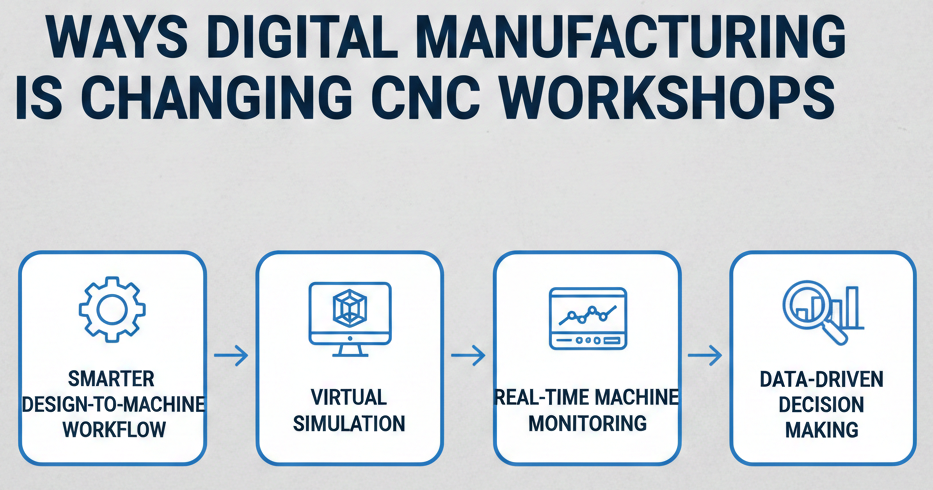

Key Ways Digitally Integrated Manufacturing Is Changing CNC Workshops

1. Improved Design-to-Machine Workflow

CAD models now flow smoothly into CAM software and CNC machines. Toolpaths are digitally optimized, which reduces uncertainty on the shop floor.

- Reduced manual mistakes

- Faster program checks

- Smooth transition from design to production

2. Virtual Simulation Before the Actual Machining

With digital simulations, CNC programmers can test machining operations before running them on real machines.

Benefits include:

- Detecting collisions

- Improved cutting methods

- Less tool damage

This can save hours of rework and costly downtime.

3. Real-Time Machine Monitoring

Sensors and CNC machines that can connect to the internet offer real-time data on:

- Spindle load

- Tool wear

- Cycle time

- Machine condition

This allows workshop managers to respond quickly instead of waiting for problems to surface later.

4. Data-Driven Decision Making

Instead of relying solely on experience, CNC workshops now use real production data to improve their processes.

- Find bottlenecks

- Improve scheduling

- Anticipate maintenance

Over time, this promotes consistent quality and predictable output.

Traditional CNC vs Digitally Run CNC

| Aspect | Traditional CNC Workshop | Digitally Run CNC Workshop |

|---|---|---|

| Programming | Manual & isolated | Integrated CAD/CAM workflow |

| Error Detection | During machining | Before machining through simulation |

| Monitoring | Manual checks | Real-time digital monitoring |

| Downtime | Reactive | Predictive and scheduled |

| Efficiency | Moderate | High and scalable |

This shows how digitally integrated manufacturing provides CNC workshops with a competitive advantage.

Benefits of CNC Workshops Experience After Going Digital

CNC shops that embrace digital tools often see improvements quickly.

Some key include:

- Less scrap and rework

- Shorter turnaround

- Better machine use

- Improved customer happiness

- More confident production planning

Digitally integrated manufacturing doesn’t replace skilled machinists – it provides them with better resources.

Challenges (And Why They’re Worth Solving)

Like any transition, digital adoption presents challenges:

- Upfront costs for software and machines

- Training operators and programmers

- Integrating old machines with new systems

But the long-term benefits – improved efficiency, scalability, and quality – outweigh the early difficulties. Many CNC workshops begin small and scale at their own pace.

Why Digitally Integrated Manufacturing Is the Future of CNC Workshops

Customer demands are increasing, tolerances are tighter, and delivery times are shorter. Without digital systems, it’s difficult for CNC workshops to keep pace.

It enables:

- Faster response to design changes

- Better control over complex parts

- Scalable growth

For companies, embracing it means delivering reliability, precision, and forward thinking. Digital manufacturing is a better approach to running CNC workshops in a competitive market. By merging human skills with digital intelligence, CNC businesses can achieve improved quality, faster delivery, and sustained growth, while also being prepared for any future challenges.

FAQs

1. Is digitally integrated manufacturing only for big CNC workshops?

No. Even small CNC shops can start with CAD/CAM integration and gradually incorporate advanced digital tools.

2. Does digitally integrated manufacturing replace skilled machinists?

No. It helps machinists by limiting manual errors and enabling them to focus on process improvements and quality.

3. How fast can improvements be seen after adoption?

Many workshops see gains in efficiency and reduced scrap within weeks of implementing these changes.

Contact Us

📞 +91 99137 89065