Manufacturing has moved beyond just machines and manual labor. Today, it involves intelligent systems, interconnected steps, and data-driven choices. We call this move Industry 4.0, and CAD/CAM tech is central to it. At Mechman Solution, we see how CAD/CAM Industry 4.0 methods transform product design, manufacturing, and testing, making the process quicker, more intelligent, and less prone to errors.

Understanding Industry 4.0

Industry 4.0 is the fourth industrial change, where production systems run on:

- Robotics and computerization

- IoT (Internet of Things)

- AI and data study

- Digital twins and cloud computing

Instead of keeping things separate, machines, software, and people share info instantly. Computer-Aided Design/Computer-Aided Manufacturing is key here, acting as the digital base for innovative production.

What is CAD/CAM and Why It Matters

Computer-Aided Design lets engineers create precise 2D and 3D models, and Computer-Aided Manufacturing converts these models into instructions for machines.

Together, they make sure:

- Design flows smoothly into production

- Mistakes are less frequent

- Products hit the market sooner

In the CAD/CAM Industry 4.0 world, CAD/CAM tools do more than design parts-they also talk to machines, sensors, and data platforms.

How CAD/CAM Supports Smart Production

Let’s look at how Computer-Aided Design/Computer-Aided Manufacturing helps factories without getting too technical.

1. Combining Digital Designs

CAD software creates innovative 3D models using data such as dimensions and materials. These models can be shared across teams right away.

This eliminates guesswork and confusion.

2. Machine Connection

CAM software links to CNC machines, robots, and computer systems, which allows for:

- Automatic creation of toolpaths

- Immediate machine updates

- Faster production

This is key to using CAD/CAM Industry 4.0.

3. Faster Creation and Changes

Need to change a design? It’s simple.

- CAD changes show up quickly

- CAM tools update machine paths on their own

- Production restarts with little delay

This makes it easier for factories to stay competitive in fast-changing markets.

How CAD/CAM Supports Modern Production

Here’s a simple way to see the change:

| Traditional Production | Industry 4.0 with CAD/CAM |

|---|---|

| Manual design changes | Automated design updates |

| Separate design & production | Integrated CAD-CAM workflow |

| More errors | Precision-driven processes |

| Limited data usage | Real-time data feedback |

This table shows why CAD/CAM Industry 4.0 is becoming the standard.

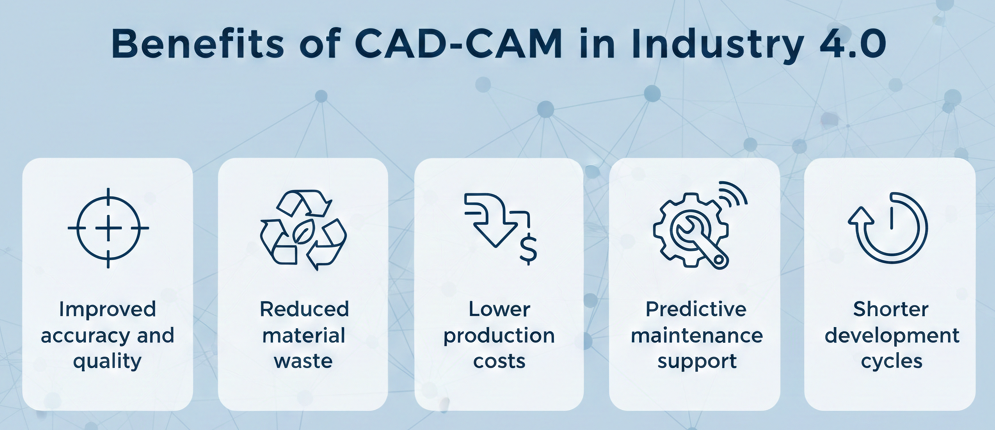

Main Benefits of CAD/CAM in Industry 4.0

CAD/CAM has been around for a while, but Industry 4.0 makes it even better.

The best parts are:

- Better exactness and quality

- Less wasted material

- Cheaper production

- Predictive maintenance

- Quicker product creation

By integrating CAD/CAM with IoT and analytics, factories can monitor how things are going and address problems before they cause financial losses. CAD/CAM is powerful because it works with tech such as:

- Digital Twins: Virtual copies of machines and products

- AI: Smarter designs and toolpaths

- Cloud: Teams working together from anywhere

This ensures that design choices are made with real data, not guesses.

CAD/CAM: Why It’s Needed for Production?

Factories that don’t adopt CAD/CAM may fall behind, as today’s customers demand faster delivery, customization, and reliable quality. With Computer-Aided Design/Computer-Aided Manufacturing Industry 4.0, businesses can move faster to meet these needs while keeping costs down. At Mechman Solution, we think CAD/CAM is more than a tool-it’s a way to get ahead in modern production.

Industry 4.0 is about working smarter, not harder. With CAD & CAM at the center, factories can easily link digital design and physical production. As tech keeps evolving, using it is essential for building a strong, modern production system.

FAQs

1. How does Computer-Aided Design/Computer-Aided Manufacturing support Industry 4.0?

CAD/CAM lets you create digital designs, automate tasks, and combine data in real time-all key to Industry 4.0 production.

2. Is CAD/CAM only useful for big factories?

No way. Small and medium-sized businesses also benefit from CAD/CAM tools because they improve accuracy, reduce waste, and speed up production.

3. Can CAD/CAM work with IoT systems?

Yes. In Industry 4.0, Computer-Aided Design/Computer-Aided Manufacturing systems often work with IoT sensors to monitor events in real time and predict the future.

Contact Us

📞 +91 99137 89065