Manufacturing is changing fast, and CNC programming is at the center of it all. If you’re a CNC programmer (or want to be), you need to stay sharp to keep up in 2026. Whether you’re a newbie or a seasoned pro, some must-have CNC programmer skills will keep you in demand.

Understanding CNC Programming Fundamentals

Before you jump into the advanced stuff, you have to nail the CNC programmer skills. CNC programming is all about giving machines clear, precise instructions to make stuff. So, every CNC programmer needs to know:

- How to read blueprints and other tech drawings.

- All about machine tools and what they do.

- The basics of G-code and M-code.

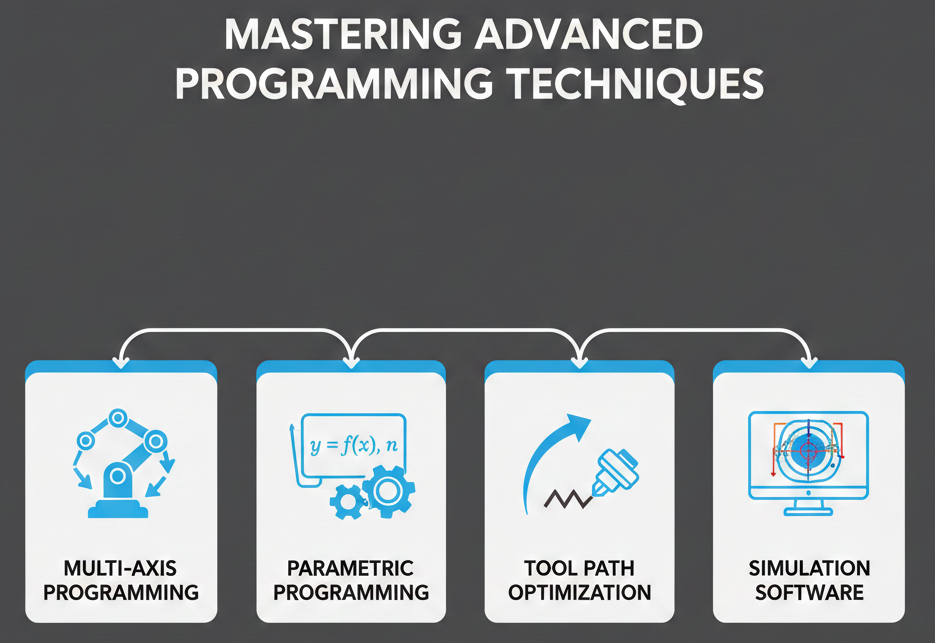

Mastering Advanced Programming Techniques

CNC machines are getting smarter, so programming is getting more complex. By 2026, you can’t just run the machine; you need to get the most out of it. Here are some key advanced skills:

- Multi-axis programming: This means working with 4-axis or 5-axis machines. It lets you cut some really complex parts in a single setup.

- Parametric programming: It’s like writing a program that can adapt to different sizes of the same product.

- Toolpath optimization: Finding the fastest way for the machine to cut something without sacrificing accuracy. Saves time and money.

- Simulation software: Testing your programs on the computer before you run them on the real machine. Catches mistakes before they cost you.

Embracing Modern CNC Software

These days, software makes programming way faster and more accurate. Every CNC programmer should learn a CAM (Computer-Aided Manufacturing) software package and keep up with updates. Here are a few to learn:

- SolidWorks CAM

- Fusion 360

- Mastercam

- Siemens NX

These programs let you design parts, test them out, and find ways to make things even better, all on your computer.

Table: Key CNC Programmer Skills in 2026

Here are some key CNC programmer skills you must learn in 2026:

| Skill Area | Importance | Tools/Techniques |

|---|---|---|

| Programming Basics | High | G-code, M-code, Tech Drawings |

| Advanced Programming | High | Multi-axis, Parametric Programming, Tool Path Optimization |

| Software Skills | Medium-High | SolidWorks CAM, Fusion 360, Mastercam |

| Problem Solving | High | Troubleshooting, Simulation |

| Communication | Medium | Teamwork, Technical Reporting |

Problem-Solving and Analytical Thinking

Good CNC programmers are also good at fixing problems. Machines mess up, and programs don’t always work right. Strong analytical skills enable programmers to identify issues and adjust programs accordingly quickly. Some critical aspects include:

- Figuring out what went wrong when a machine stops working.

- Knowing what’s happening to your tools and materials

- Optimizing speed and feed to get the best results.

If you can spot problems early, you’ll keep things running smoothly and save a ton.

Communication and Team Collaboration

CNC programming might seem like a solo job, but you’ve got to be able to talk to people. You’ll work with designers, engineers, and the people who run the machines. Being able to explain things clearly is a huge deal. CNC programmer skills include:

- Explain tech stuff to non-technical staff.

- Write down how your programs work so others can use them.

- Work with engineers to improve designs for better machinability.

Good communication makes everyone’s job easier.

Continuous Learning: Staying Ahead in 2026

Manufacturing is constantly changing, so you have to keep learning. Things like AI in programming, connected machines, and new materials are changing the game. You can improve by taking online classes and going to workshops, reading blogs and forums, and trying out new tech in the shop.

Being a CNC programmer in 2026 means knowing traditional tech, working with modern software, and solving problems. If you focus on these things and always keep learning, you’ll be successful, adapt to changes, and be ready to tackle whatever the future brings.

If you keep learning, you’ll be ready for whatever comes next.

FAQs

1. How long does it take to get good at CNC programming?

Usually, it takes a year or three of doing it to learn both the basics and some more advanced stuff.

2. Do I really need to learn software like Fusion 360?

Yes. Modern CNC programming uses software. Knowing tools like Fusion 360 makes you way more valuable.

3. Can an AI program run CNC machines all by itself?

Not completely. AI helps, but you still need people to fix problems, pick tools, and make sure everything’s good.

Contact Us

📞 +91 99137 89065