Computer Numerical Control (CNC) machining is an essential component in today’s fast-paced production industry, allowing for the manufacture of precise and complicated parts for a wide range of sectors. To remain competitive, manufacturers are increasingly using innovative technologies as the need for speed, precision, and automation grows. Autodesk products like PowerMill and FeatureCAM have become industry leaders with their innovative capabilities that revolutionize CNC programming and machining. To shed light on the future of smart manufacturing, this blog examines the progress of CNC machining, the revolutionary potential of PowerMill and FeatureCAM, and how they fit into the Industry 4.0 framework.

Understanding the Current CNC Landscape

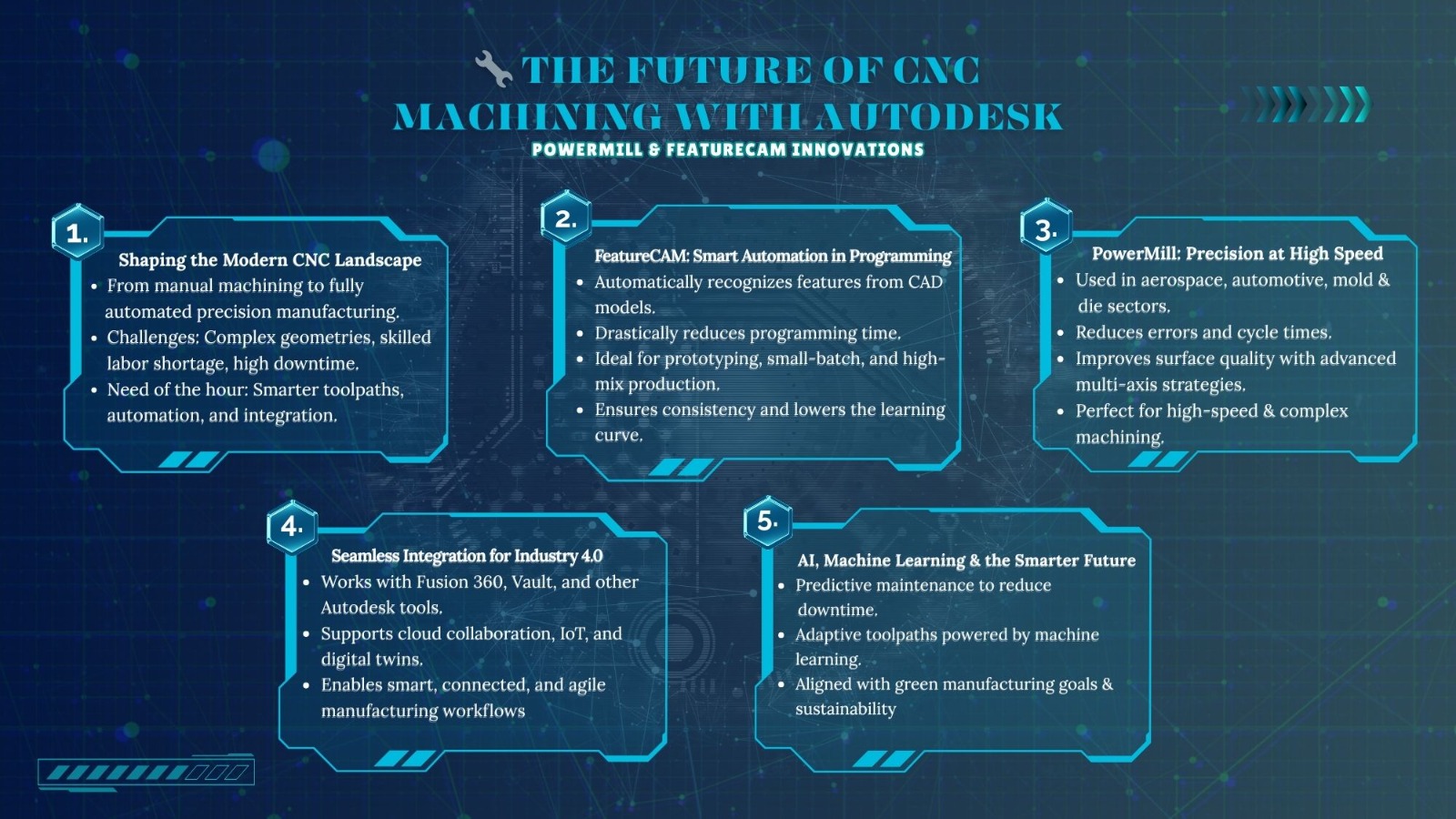

CNC machining has evolved significantly over time. The journey depicts an unending drive for precision and efficiency, progressing from manual to automated methods. Complex geometries, a scarcity of skilled workforce, and the desire to decrease downtime are some of the challenges confronting the industry today. These features emphasize the need for automation and smart toolpaths to maintain a competitive advantage.

PowerMill has been utilized by the automotive, aerospace, and mold and die industries to decrease errors, improve surface qualities, and shorten cycle times. As one of the most powerful Autodesk products, it plays a vital role in helping manufacturers meet today’s challenges with smarter, faster, and more precise toolpaths.

FeatureCAM: Automating CAM Like Never Before

FeatureCAM‘s emphasis on automation and feature recognition changes CNC programming. It improves the process of producing toolpaths by automatically detecting manufacturing properties from solid or surface models, significantly reducing programming time.

Prototyping, high-mix, low-volume manufacturing, and small-batch operations benefit most from this automation, as it lowers the entry barrier for complex machining procedures and ensures consistent outcomes. These capabilities further reinforce the value of Autodesk products in modern, flexible production environments.

Integration, Cloud, and Industry 4.0 Compatibility

PowerMill and FeatureCAM provide greater cooperation and data management through their smooth integration with Autodesk’s larger ecosystem, which includes Fusion 360 and Vault. Real-time data interchange is made possible by the use of cloud-based technologies, which also help achieve Industry 4.0 goals like digital twins and IoT-ready production. This integrated strategy guarantees that production procedures are both effective and flexible enough to accommodate upcoming technological developments.

The Future is Smarter: What’s Next?

Developments in AI and machine learning provide light on the future of CNC machining. AI-powered predictive maintenance reduces unplanned downtime by anticipating machine faults through the analysis of past and current data. Furthermore, adaptable toolpaths that can instantly adapt to machining circumstances are being made possible by machine learning algorithms, which will increase accuracy and productivity. These intelligent systems support energy-efficient machining techniques, which are in line with international environmental goals as sustainability gains attention.

Autodesk products are continuously evolving to embrace these technologies, ensuring that manufacturers are equipped for a smarter, more sustainable future.

Why Your Shop Should Adopt These Tools Today

Using FeatureCAM with PowerMill offers major benefits:

- Cost and Productivity Gains: Automation reduces operational costs and accelerates production turnaround times by decreasing manual intervention.

- Competitive Advantage: Keeping up with technological developments puts your shop in a leadership position in a market that is changing quickly.

- Skill Development: Having access to innovative resources encourages your employees to keep learning and improving their skills.

- Community and Assistance: As a member of the Autodesk ecosystem, you have access to a multitude of expert assistance, forums, and tutorials that will help you get the most out of these tools.

In Conclusion

Autodesk products like PowerMill and FeatureCAM, which have established the norm for CNC machining innovations, help organizations overcome today’s production problems and be ready for the smart manufacturing age. Introducing these technologies into your workflow is more than just an upgrade; it’s a deliberate step toward greater accuracy, efficiency, and sustainability. Are you prepared for the future of CNC machining?

Find out how FeatureCAM and PowerMill may improve your machining skills. The moment to take action is now, regardless of your goals: future-proof your workshop, optimize intricate toolpaths, or cut down on programming time.

Book a free demo with Mechman Solution — your trusted Autodesk partner.

Learn how these tools may be customized to meet your unique manufacturing requirements.

Start your journey toward smart, efficient, and scalable CNC machining. Let’s build the future of manufacturing, one toolpath at a time.

👉 Contact us today to book a free demo or training consultation.

📩 mechmansolution@gmail.com | 📞 +91 99137 89065 | 🌐 www.mechmansolution.com

Also Read: Why PowerMill And FeatureCAM Are Among The Best CAD CAM Software In India?