Modern manufacturing is driven by CNC machining, which provides accuracy and efficiency across industries. Choosing the right CAD CAM software is essential for optimizing toolpaths, cutting down on cycle times, and guaranteeing accuracy. Autodesk’s PowerMill and FeatureCAM are two industry-leading solutions with unique machining requirements. The following article evaluates their features to help you select the one that best suits your CNC operations.

Understanding the Basics

CAD CAM software connects design and production by converting 3D models into machine-readable instructions for CNC machinery. It manages automation, simulation, and toolpath creation to guarantee precise and effective component machining. Software selection is crucial for success because these technologies integrate design (CAD) and manufacturing (CAM), optimize processes, reduce errors, and boost productivity.

Overview of Autodesk PowerMill

A high-performance CAM system made for intricate, precision-driven milling is called PowerMill. It offers sophisticated toolpath methods for high-speed machining and complex mold design, and it performs very well in 3-, 4-, and 5-axis operations. Adaptive clearing, dynamic machine control, and automatic collision avoidance are essential characteristics that guarantee excellent surface finishes. Though its steep learning curve might be difficult for beginners, PowerMill’s strength lies in its accuracy and customization, making it ideal for heavy industries, mold-making, aerospace, and automotive.

Overview of Autodesk FeatureCAM

FeatureCAM is an easy-to-use CAD CAM software platform that prioritizes automation and adaptability. Programming is made easier by its automatic feature identification, which recognizes component geometries (such as holes and pockets) and quickly creates toolpaths. Together with integrated CAD/CAM capabilities for smooth operations, it provides wire EDM, milling, and turning. FeatureCAM’s simplicity of use is a significant asset, but it is less reliable for complex 5-axis jobs than PowerMill. FeatureCAM best suits job shops, small-to-medium businesses, and high-mix, low-volume production.

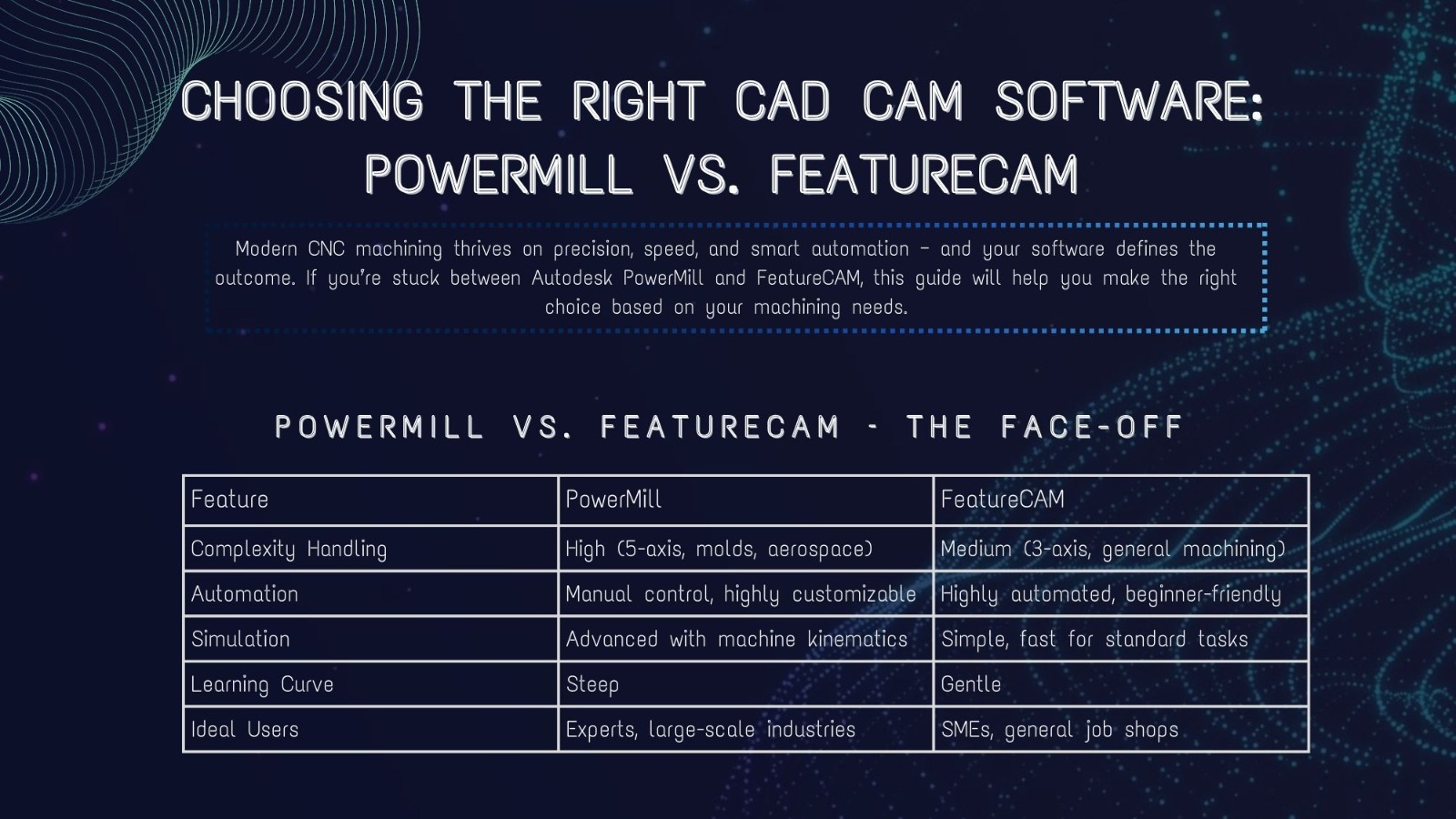

Key Differences Between PowerMill and FeatureCAM

- Machining Complexity: FeatureCAM performs better on basic 3-axis and turning jobs, while PowerMill’s sophisticated 5-axis capability manages complex geometries like turbine blades.

- User Interface: While PowerMill’s extensive customization appeals to professionals requiring granular control, FeatureCAM’s user-friendly interface is better suited for beginners.

- Automation vs. Control: PowerMill provides precise control for intricate tasks, whereas FeatureCAM emphasizes automation for speedy setups.

- Simulation and Verification: FeatureCAM’s simulation is more straightforward but still efficient for routine tasks, whereas PowerMill’s simulation, which uses machine kinematics, offers accurate error detection.

- Toolpath Strategies: For high-precision requirements, PowerMill’s multi-axis finishing and adaptive clearing perform better than FeatureCAM’s simple roughing and finishing.

How to Choose the Right Software for Your Needs

- Project Complexity and Scale: FeatureCAM performs well in smaller, repetitive batch manufacturing, whereas PowerMill is best suited for large-scale, complex projects (such as aerospace components).

- Industry Requirements: PowerMill’s accuracy is essential for mold-making and aerospace, while FeatureCAM’s speed is advantageous for general machining or job shops.

- Skill Level: Advanced users benefit from PowerMill’s customizability, while beginners thrive on FeatureCAM’s simplicity.

- Monetary Considerations: PowerMill’s premium price suits businesses with high-value projects, whereas FeatureCAM’s reduced cost appeals to SMEs.

- Integration Features: Both assure compatibility with your CNC controllers using post-processors and integrate with Autodesk programs (like Inventor).

Case Studies and Real-World Applications

Titanium aircraft components were machined by an aerospace company using PowerMill, which achieved ±5-micron tolerances and 30% shorter cycle times with 5-axis toolpaths. By employing PowerMill’s adaptive techniques, a mold-making company improved delivery timelines by reducing programming time by 25%. On the other hand, FeatureCAM was used by a workshop that made bespoke brackets, automating toolpath creation and reducing setup times by 40%. Using FeatureCAM’s feature identification, a small components manufacturer experienced a 50% quicker turnaround on high-mix orders. These examples demonstrate the accuracy of PowerMill for intricate operations and the effectiveness of FeatureCAM for high-volume, simpler work.

In Conclusion

FeatureCAM and PowerMill serve different CAD CAM software needs for CNC machining requirements. PowerMill provides unparalleled control and surface quality in high-precision, intricate 5-axis projects for sectors like mold-making and aerospace. FeatureCAM excels in automated, intuitive programming for SMEs and job shops that handle smaller items. When selecting CAD CAM software, consider the budget, talent level, industry expectations, and project complexity. FeatureCAM excels at rapid, repetitive operations, whereas PowerMill is the preferred tool for complex, high-value work. FeatureCAM excels at rapid, repetitive operations, whereas PowerMill is the preferred tool for complex, high-value work. To choose the software that propels your achievement, assess your objectives.

The moment to take action is now, regardless of your goals: future-proof your workshop, optimize complex toolpaths, or reduce programming time.

Mechman Solution, your reliable Autodesk partner, offers a free demo.

Learn how FeatureCAM or PowerMill may meet your production demands in a customized way.

Begin your path to intelligent, effective, and scalable CNC machining. One toolpath at a time, let’s construct the manufacturing of the future.

👉 Contact us today to book a free demo or training consultation.

📩 mechmansolution@gmail.com | 📞 +91 99137 89065 | 🌐 www.mechmansolution.com

Also Read: How Autodesk PowerMill Enhances Efficiency in High-Speed Machining Compared to Other CAM Software