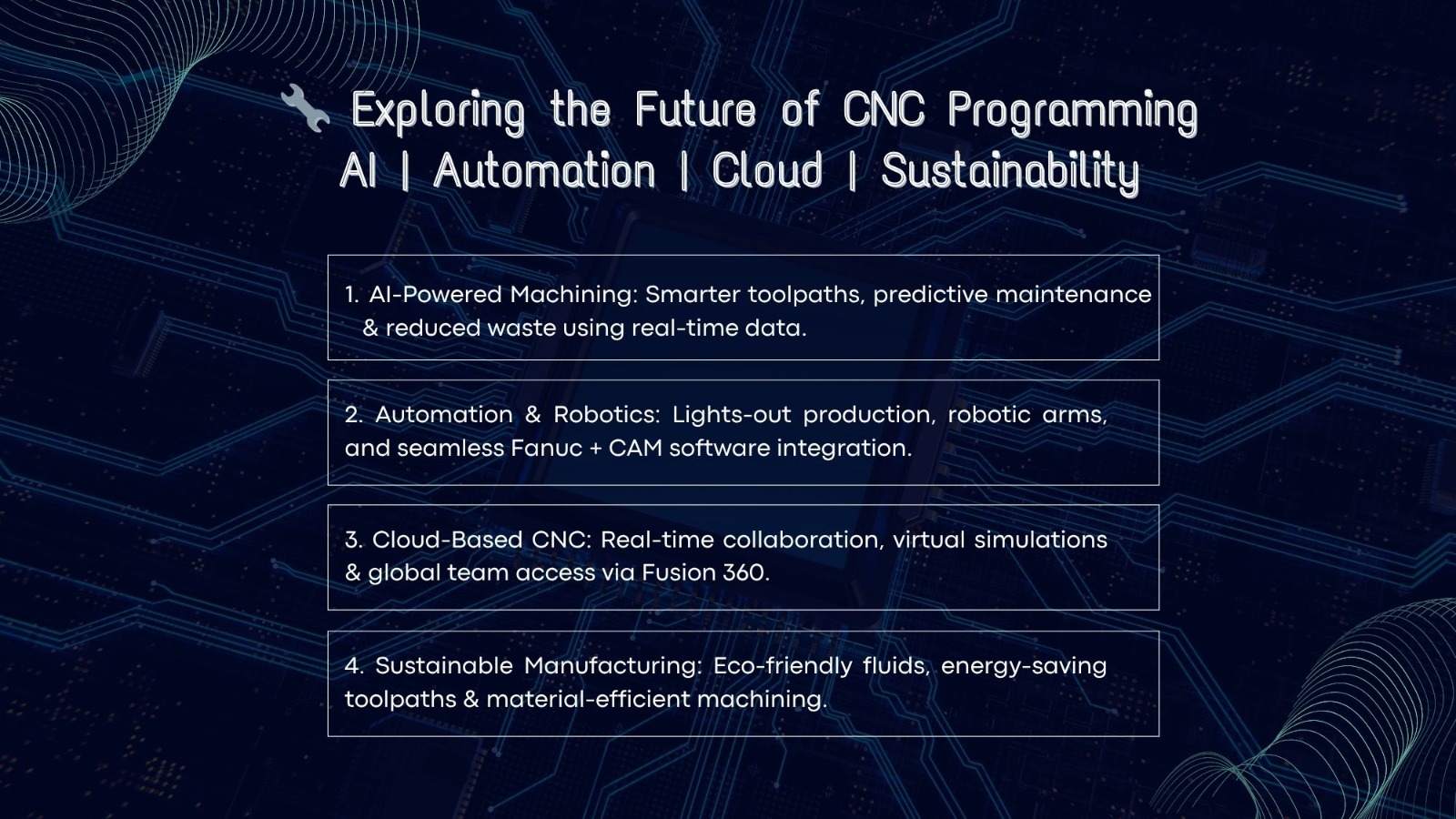

The world of CNC (Computer Numerical Control) programming is evolving at a breakneck speed with the help of technologies that advance manufacturing accuracy, productivity, and scalability. With industries requiring quicker output and higher quality, innovations such as artificial intelligence (AI), automation, cloud-based systems, and eco-friendly techniques are revolutionizing CNC programming.

AI-Powered CNC Programming

Artificial intelligence is transforming CNC programming to facilitate smarter, data-based decisions.

AI algorithms analyze real-time machining data to predict tool wear, optimize toolpaths, and reduce material waste. For instance, in 4-axis VMC (Vertical Machining Center) setups, AI adjusts cutting parameters dynamically to maintain precision across complex geometries, minimizing errors and enhancing part quality for aerospace and medical devices.

AI also drives predictive maintenance, monitoring machine performance to prevent failures, reduce downtime, and extend equipment lifespan. By integrating AI with CAM (Computer-Aided Manufacturing) software like Autodesk PowerMill, programmers can create efficient toolpaths for multi-axis tasks, balancing speed and accuracy. Over time, AI takes over routine activities and frees programmers to work on innovation and strategic issues, forming a foundation of contemporary CNC work.

Automation and Robotics Integration

Automation simplifies CNC operations by minimizing manual effort and increasing productivity. Automatic tool changers, robotically enabled arms, and automated handling systems interface easily with CNC machines to carry out activities such as part loading, inspection, and tool calibration. This facilitates lights-out production, wherein machines run overnight without human intervention, optimizing production in high-volume production settings such as the automotive and aerospace industries.

Combining Fanuc CNC controllers with robotic systems ensures repeatability in tasks like milling or turning. CAM software like Autodesk FeatureCAM simplifies automation by generating machine-specific code, reducing setup times and errors. These advancements democratize automation, enabling small and medium enterprises to achieve cost-efficient, high-quality production.

Cloud-Based CNC Programming Solutions

Cloud-based platforms are revolutionizing project and collaboration management in CNC programming. Platforms like Autodesk Fusion 360 offer a central location from which to access, modify, and share machining projects in real time, perfect for global users who collaborate across time zones. Virtual simulation technology within these platforms enables programmers to simulate toolpaths and identify collisions ahead of machining, thereby reducing time and materials.

Cloud solutions also capture performance metrics so workflows can be data-driven and optimized. Beginners also benefit from Fusion 360’s ease of use and cloud accessibility, reducing the learning curve and serving as a versatile option for new and veteran programmers. These platforms ensure manufacturers stay agile and competitive in a fast-paced industry.

Sustainability in CNC Programming

Sustainability is a growing priority in CNC programming as manufacturers aim to reduce environmental impact. Advanced CAM software optimizes toolpaths to minimize energy consumption and material waste, aligning with green manufacturing goals. For example, PowerMill’s high-speed machining strategies enable efficient material removal while reducing power usage.

Programmers adopt eco-friendly practices, such as biodegradable cutting fluids and recycling scrap metal. AI enhances sustainability by analyzing machining data to recommend energy-efficient parameters. As regulatory pressures increase, these innovations help manufacturers meet sustainability targets while maintaining profitability, positioning CNC programming as a driver of eco-conscious production.

The Role of Advanced CAM Software

Advanced CAM software is the backbone of CNC programming, enabling integration with AI, automation, and cloud technologies. Autodesk PowerMill excels in high-speed, multi-axis machining, offering robust toolpath optimization for complex parts. Its precision makes it ideal for industries requiring tight tolerances.

Autodesk FeatureCAM, conversely, simplifies programming for automation-focused workflows, generating machine-ready code with minimal input. PowerMill suits precision-driven projects, while FeatureCAM prioritizes speed and ease. Both tools leverage cloud platforms and AI, ensuring programmers can adapt to evolving demands and maintain a competitive edge.

Training for the Future

These skills must be constantly learned. Training courses in Fusion 360, PowerMill, and FeatureCAM prepare programmers to capitalize on AI, automation, and cloud technology. These courses emphasize hands-on applications like optimizing Fanuc post processors or robotics integration so professionals can tackle real challenges.

Autodesk’s online training courses provide hands-on exercises and certification, closing the gap between old-school computer-aided manufacturing techniques and cutting-edge technology-based methods. Training is essential to career development as it enables programmers to tackle the future of manufacturing confidently.

Explore how Autodesk FeatureCAM and PowerMill can revolutionize your machining. Are your goals to future-proof your workshop, improve complex toolpaths, or reduce programming time?

The time to do so is now. With Mechman Solutions as your trusted Autodesk partner, tap into the full power of these solutions, which are explicitly designed to suit your individual manufacturing goals.

Schedule a free training or demo today and begin your path toward efficient, scalable, and more innovative CNC machining. Together, we can shape the future of manufacturing one toolpath at a time.

👉 Contact Mechman Solutions now.

📩 mechmansolution@gmail.com 📞 +91 99137 89065 🌐 www.mechmansolution.com

Also Read: Why Taking A Fusion 360 Course Can Elevate Your CNC And Product Design Skills