Today’s competitive environment for manufacturers can make producing perfect plastic parts essential. Warpage, sink marks, or voids create additional costs but will slow down production. Autodesk Moldflow is one of the best simulation software packages used in the manufacturing industry to identify and solve issues before they happen.

At Mechman Solution, we use Autodesk Moldflow to help clients optimize their injection molding processes, saving time, reducing costs, and ensuring superior product quality. This guide explains how Moldflow works, why it matters, and how businesses benefit from it.

What Is Autodesk Moldflow, and Why Does It Matter?

Autodesk Moldflow is a simulation software designed to analyze and improve the plastic injection molding process. Instead of relying on trial-and-error, engineers can test virtual models before making physical molds.

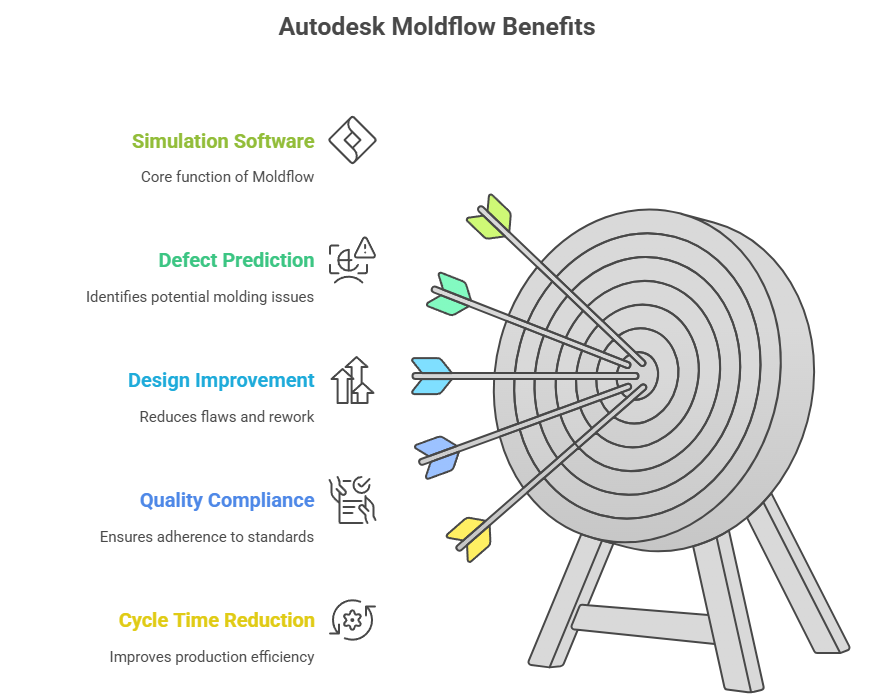

Why it’s important:

- Predicts molding defects before production.

- Reduces design flaws and costly rework.

- Improves compliance with quality standards like ISO 9001.

- Cuts cycle times by 20–30% in some cases.

By combining finite element analysis (FEA) with an extensive material database, Moldflow shows how molten plastic flows, cools, and solidifies. This makes it easier to achieve consistent, high-quality results across industries like automotive, electronics, and consumer goods.

How Does Moldflow Predict and Prevent Defects?

Plastic injection molding undergoes several stages: filling, packing, cooling, and ejection. Moldflow simulates each step to highlight problems that might affect part strength or appearance.

Important predictions for defects include:

- Weld lines and air traps: Can weaken parts; Moldflow recommends better designs for runners or gates.

- Short shots & overpacking: Packing analysis prevents incomplete or stressed parts.

- Warpage & shrinkage: Cooling simulation identifies hotspots and improves cooling channel layouts.

By making adjustments virtually, manufacturers avoid repeated mold trials and achieve better dimensional accuracy from the start.

How Does Moldflow Reduce Material Waste and Costs?

Plastic resin is expensive. Wasting it through bad designs or inadequate process control can significantly increase costs. Autodesk Moldflow helps optimize material use and improve sustainability.

Benefits for manufacturers:

- Lower prototyping costs with virtual design iterations.

- Reduced energy use thanks to shorter cycle times.

- Greener manufacturing by minimizing waste and emissions.

Integration with CAD software, such as Autodesk Inventor, makes the workflow smoother, allowing engineers to test multiple scenarios before committing to tooling.

How Does Moldflow Support Team Collaboration and Compliance?

Injection molding projects involve numerous stakeholders, including designers, mold makers, and quality teams. Moldflow makes collaboration easier with clear, shareable insights.

- 3D animations and reports help teams visualize issues.

- Data transparency supports decision-making across departments.

- Compliance readiness with traceable process parameters for audits and inspections.

- Risk reduction by testing worst-case scenarios for regulated industries (e.g., medical devices, automotive).

Where Has Moldflow Shown Its Value in Practice?

The benefits of Moldflow are industry-wide:

- Automobiles: Comparatively less warpage by optimizing bumpers and dashboards.

- Electronics: Improved encapsulation of delicate components; prevented voids.

- Consumer goods: Eliminated surface defects for better aesthetics.

Its versatility works with materials ranging from standard thermoplastics to fiber-reinforced composites. The result? Reliable, defect-free products that meet customer expectations and industry standards.

Benefits of Autodesk Moldflow vs Traditional Trial-and-Error

| Feature | Traditional Approach | With Autodesk Moldflow |

|---|---|---|

| Defect Detection | After the mold is built | Before production starts |

| Material Waste | High | Reduced |

| Prototyping Cost | Expensive and repetitive | Virtual testing saves costs |

| Cycle Time Optimization | Limited | Up to 30% faster cycles |

| Compliance Support | Manual checks | Automated, data-driven reports |

| Collaboration | Fragmented communication | Shared 3D reports and visuals |

Are You Ready for Higher-Quality Injection Molding?

Autodesk Moldflow is a competitive advantage, not just software. Predicting defects, reducing waste, and improving compliance help manufacturers save money while delivering top-quality products.

Want to see how it works for your business?

- Contact Mechman Solution for a free consultation.

- Schedule a live demo with our experts.

- Discover how simulation can transform your injection molding process.

Take the first step toward more innovative, more efficient, and sustainable manufacturing today.

📩 mechmansolution@gmail.com | 📞 +91 99137 89065 | 🌐 www.mechmansolution.com

Also Read: How Autodesk Fusion 360 is Transforming Product Design for SMEs in Gujarat