Gujarat’s industry, covering automotive, aerospace, plastics, and engineering sectors, is reliant on the most advanced tools to stay competitive. Manufacturers use specialized software tools to produce complex designs with shorter production lead times. This requires speed in addition to precision from their software tools. Autodesk PowerShape has become the go-to solution, enabling engineers to model intricate molds, dies, and electrodes with confidence.

At Mechman Solution, we help businesses in Gujarat harness PowerShape to optimize their tooling workflows. This article explores how PowerShape addresses design challenges, improves efficiency, and ensures quality in Gujarat’s high-stakes manufacturing environment.

What Is Autodesk PowerShape and Why Does Gujarat Rely on It?

Autodesk PowerShape is a specialized CAD software designed for creating detailed 3D models of molds, dies, and complex parts. Unlike traditional CAD tools, it combines solid, surface, and mesh modeling techniques to handle designs that standard tools cannot.

Why it matters for Gujarat’s industries:

- Handles intricate geometries standard in automotive and aerospace components.

- Offers automation tools like core/cavity splitting and electrode design.

- Reduces design iteration time, helping meet tight deadlines.

- Integrates with Autodesk Fusion, enabling smooth collaboration across teams.

PowerShape is an essential tool for Gujarat’s manufacturing ecosystem because of its versatility, as efficiency and accuracy have a direct impact on competitiveness.

Which Features Make PowerShape Ideal for Complex Tooling?

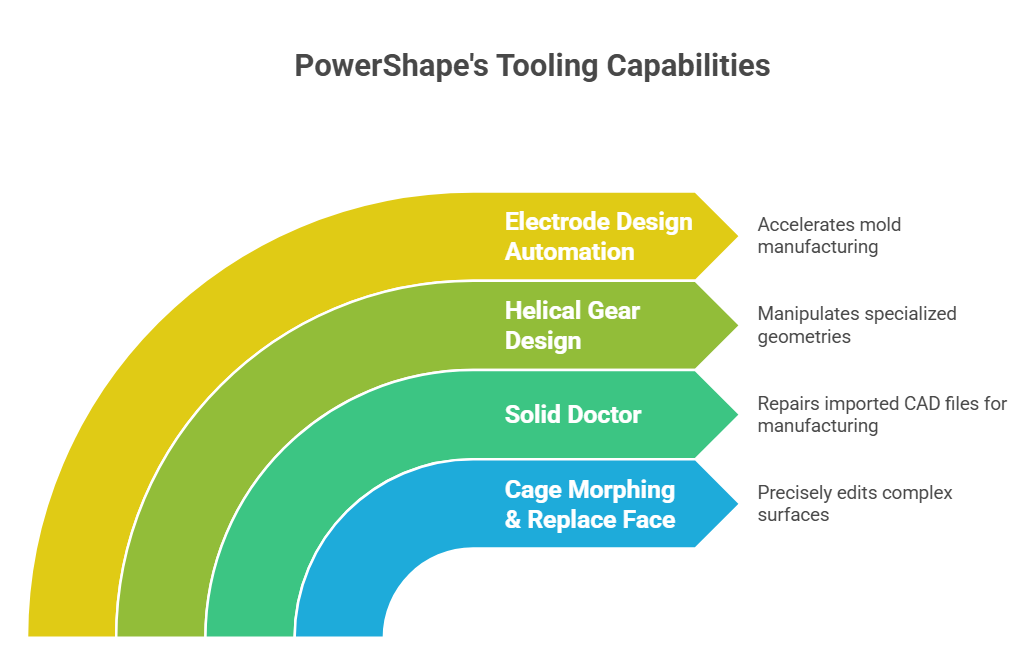

Tooling for high-performance sectors often involves non-standard and highly detailed shapes. PowerShape provides features tailored to such challenges:

- Cage morphing & replace face: Precisely edit or distort complex surfaces.

- Solid doctor: Facilitates effortless manufacturing by automatically repairing any imported CAD files.

- Helical gear design: Manipulates highly specialized geometries.

- Electrode design automation: Accelerates mold manufacturing.

These tools are handy for Gujarat’s industries producing automotive dies, aerospace molds, and high-precision plastic tooling. By reducing design errors upfront, manufacturers cut costly rework later in production.

How Does PowerShape Save Costs and Improve Efficiency?

Gujarat’s manufacturers face constant pressure to reduce costs while maintaining high quality. PowerShape integrates with PowerMill and other CAM tools, delivering significant efficiency gains.

Key benefits include:

- Indian users reported up to 30% faster production cycles.

- 20% less material waste thanks to optimized designs.

- Early detection of flaws through toolpath simulation reduces rejections.

- Improved output per shift with macro automation (25% more machining hours).

The efficiency also supports the push for sustainable manufacturing in Gujarat, which allows a reduction in energy consumption and material waste while enhancing profits.

What Impact Does PowerShape Have in India Based on Real-World Examples?

While Gujarat’s Indian manufacturers offer convincing evidence of PowerShape’s efficacy, though specific case studies are still being developed:

- Prime Graphite Pvt. Ltd.: Achieved 30% faster production and 50% fewer rejections with PowerShape.

- Marvel Machining Systems (Coimbatore): Reduced cycle times by 30% in aerospace tooling.

- CIRES India: Cut cycle times by 15–20% for complex parts using vortex machining.

These success stories mirror Gujarat’s industrial needs, where speed, precision, and cost efficiency are non-negotiable.

How Does PowerShape Support Collaboration and Compliance in Gujarat?

Collaboration and compliance are critical in Gujarat’s regulated sectors like automotive and aerospace. PowerShape helps manufacturers meet these demands:

- 3D visualizations & reports keep designers and machinists aligned.

- Traceable data supports audits for ISO and other certifications.

- Integration with PowerInspect ensures dimensional accuracy.

- Simulation of worst-case scenarios reduces risks of non-conformance.

With Mechman Solution’s expertise, Gujarat’s firms can integrate PowerShape smoothly, meeting both performance and compliance standards.

PowerShape vs Traditional CAD for Gujarat’s Manufacturing

| Feature | Traditional CAD Tools | Autodesk PowerShape |

|---|---|---|

| Handling Complex Geometries | Limited | Advanced solid, surface & mesh |

| Error Repair | Manual fixes needed | Automatic with Solid Doctor |

| Electrode & Mold Design | Time-consuming | Automated & accurate |

| Cycle Time Efficiency | Standard output | Up to 30% faster |

| Material Waste | Higher scrap rates | Reduced by ~20% |

| Compliance & Collaboration | Fragmented workflows | Integrated reports & auditing |

Ready to Transform Tooling with Autodesk PowerShape?

Autodesk PowerShape is more than CAD software; it’s a competitive advantage for Gujarat’s manufacturers. From handling complex designs to saving costs and ensuring compliance, it delivers measurable value across industries.

Want to explore PowerShape for your business?

Contact Mechman Solution for a tailored consultation.

Request a live demo with our certified experts.

Learn how PowerShape can help you accelerate production, reduce costs, and stay ahead of competitors.

Take the first step toward smarter, more efficient tooling in Gujarat today.

📩 mechmansolution@gmail.com | 📞 +91 99137 89065 | 🌐 www.mechmansolution.com

Also Read: Exploring the Latest Trends in CNC Programming: AI, Automation, and More