India is quickly becoming a global center for additive manufacturing (AM), driven primarily by rapid growth in aerospace, automotive, and healthcare. Driven by initiatives such as Make in India and the burgeoning demand for advanced prototyping, adoption has spread rapidly across industries. At the center of this transformation is Autodesk Netfabb, a powerful software solution that bridges the gap between design and production in 3D printing. With Mechman Solution as a trusted partner, Indian manufacturers are using Netfabb to reduce errors, cut costs, and scale innovation.

What Is Autodesk Netfabb and Why Is It Vital in India?

Autodesk Netfabb enables additive manufacturing workflows for preparing, simulating, and optimizing 3D models for production. It helps users to verify models will print, while also being cost-effective and durable.

Prominent features include:

- Mesh repair, which fixes or completes broken models.

- Part orientation, which accounts for print time and defects in a build cycle.

- Support generation, which ensures a design supports itself for stability and reliability.

- Latticing and hollowing designs, which use less material during the build cycle.

- Packing and nesting designs, which optimize the maximum capacity for the printer.

- Toolpath and slicing (over 200 printers supported).

For Indian industries that balance innovation with affordability, these tools help overcome challenges such as design complexity, frequent build failures, and limited resources.

How Does Netfabb Streamline the Workflow from Design to Production?

Additive manufacturing success depends on smooth coordination from CAD design to final part production. Netfabb provides a connected workflow that eliminates bottlenecks.

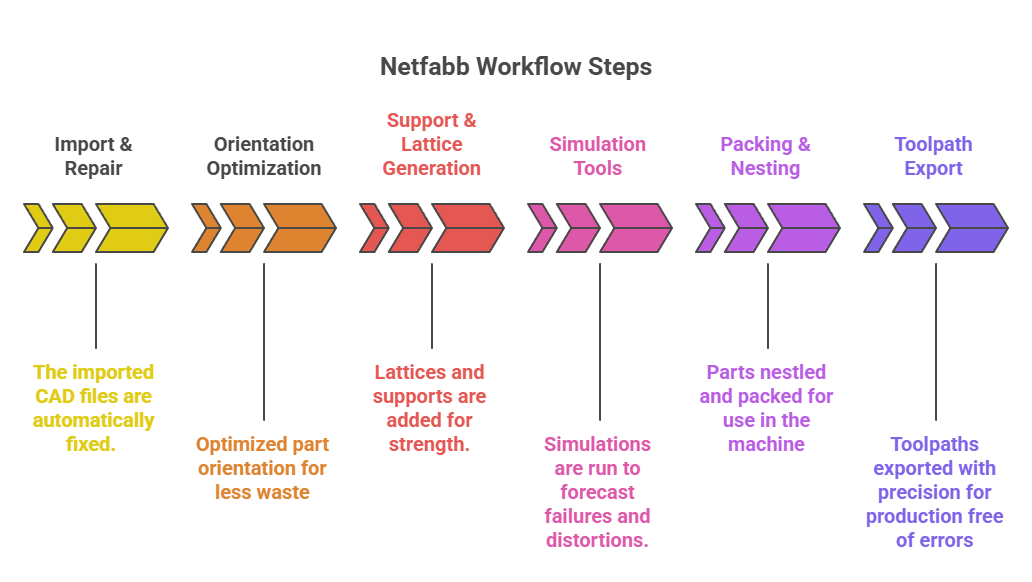

Step-by-step workflow with Netfabb:

- Import CAD files and perform automatic repairs.

- Optimize part orientation for minimal material waste.

- Generate supports and lattices for strength and lightweighting.

- Run simulation tools to predict distortions and failures.

- Use packing and nesting to maximize machine utilization.

- Export precise toolpaths for error-free production.

In India, where rapid prototyping is essential, this streamlined process cuts cycle times and accelerates market entry.

What Features Make Netfabb Ideal for Indian Manufacturers?

Indian industries handle a wide range of materials, from lightweight aerospace alloys to medical-grade titanium and various polymers. Netfabb’s advanced features make it adaptable across sectors:

- Advanced mesh editing: Repairs complex geometries automatically.

- Lattice optimization: Creates lightweight yet strong structures.

- Hollowing tools: Reduce material consumption and costs.

- Process simulation: Predicts heat distortion and shrinkage in metals.

- Automation through scripting: Minimizes repetitive manual work.

For SMEs in India, Netfabb’s integration with Autodesk Fusion also makes it more accessible and easier to adopt without high infrastructure costs.

How Does Netfabb Help Reduce Costs and Improve Efficiency?

Cost efficiency is one of the biggest challenges for Indian manufacturers. Netfabb delivers measurable savings by minimizing failures and maximizing throughput.

Benefits for cost and efficiency:

- Fewer build failures, saving both time and raw material.

- Faster design preparation with automated repair and slicing.

- Improved machine utilization, boosting output per shift.

These savings not only reduce operational costs but also support India’s sustainability goals in manufacturing by lowering energy use and waste.

What Real-World Examples Show Netfabb’s Impact in India?

Several Indian organizations have already embraced Netfabb to enhance their AM processes:

- Imaginarium: Uses Netfabb for end-to-end data preparation, improving service delivery in 3D printing.

- Curiosity 3D: Leverages Netfabb and Fusion for training, helping India build a skilled workforce in AM.

- Aerospace & Healthcare firms: Apply Netfabb’s simulation tools to design lightweight parts and implants, significantly reducing time-to-market.

These examples reflect how Netfabb adapts to India’s diverse AM ecosystem, from prototyping startups to large-scale industrial production.

How Does Netfabb Improve Collaboration and Compliance?

In regulated industries like aerospace and healthcare, collaboration and compliance are critical. Netfabb supports both:

- Shared reports & visualizations: Keep teams aligned.

- Integration with Autodesk ecosystem: Smooth data exchange across departments.

- Simulation data for validation: Ensures compliance with ISO, FDA, and industry standards.

For Indian firms aiming at global competitiveness, this combination of innovation and compliance is a game-changer.

Netfabb vs Traditional 3D Printing Tools in India

| Feature | Traditional Tools | Autodesk Netfabb |

|---|---|---|

| Mesh Repair | Manual fixes are error-prone | Automatic, reliable |

| Build Simulation | Limited or none | Predicts failures early |

| Lattice & Hollow Structures | Basic or external add-ons | Built-in, highly optimized |

| Material Efficiency | Higher waste | Less waste |

| Printer Compatibility | Restricted | 200+ printers supported |

| Automation | Minimal | Advanced scripting & macros |

Ready to Advance Your Additive Manufacturing with Netfabb?

Autodesk Netfabb is more than a 3D printing tool; it’s a complete ecosystem that helps Indian manufacturers reduce costs, boost efficiency, and stay globally competitive.

👉 Want to explore Netfabb for your business?

- Contact Mechman Solution for expert guidance.

- Request a customized demo tailored to your production needs.

- Learn how Netfabb can help you scale additive manufacturing with confidence.

Take the next step in India’s additive manufacturing revolution today.

📩 mechmansolution@gmail.com | 📞 +91 99137 89065 | 🌐 www.mechmansolution.com

Also Read: How Autodesk Fusion 360 is Transforming Product Design for SMEs in Gujarat