Customers now expect quick deliveries, top-notch quality, and prices that won’t break the bank-all at once. That’s where CAM automation quietly steps in to change the game. Instead of wasting hours on the repetitive, boring parts of programming, manufacturers can rely on automation to streamline workflows, reduce errors, and lower costs without sacrificing quality.

At Mechman Solution, we’re seeing a growing trend of companies taking on automated CAM tools, not just as something nice to have, but as a real need to stay ahead.

What’s Automation in CAM Software

CAM, or Computer-Aided Manufacturing, software helps convert CAD designs into instructions that machines can read. Automation enhances this by reducing manual work during programming, setup, and toolpath creation.

Simply put, CAM automation allows the software to:

- Make toolpaths automatically.

- Use set machining strategies.

- Pick tools and cutting settings.

- Adjust processes based on material and machine information.

Instead of always starting from scratch, programmers can work smarter by letting the software handle repeated choices.

Why Are Manufacturers Moving to Automation

Manual CAM programming is okay, but it has its limits. As production increases and parts become more complex, depending solely on manual methods can slow everything down.

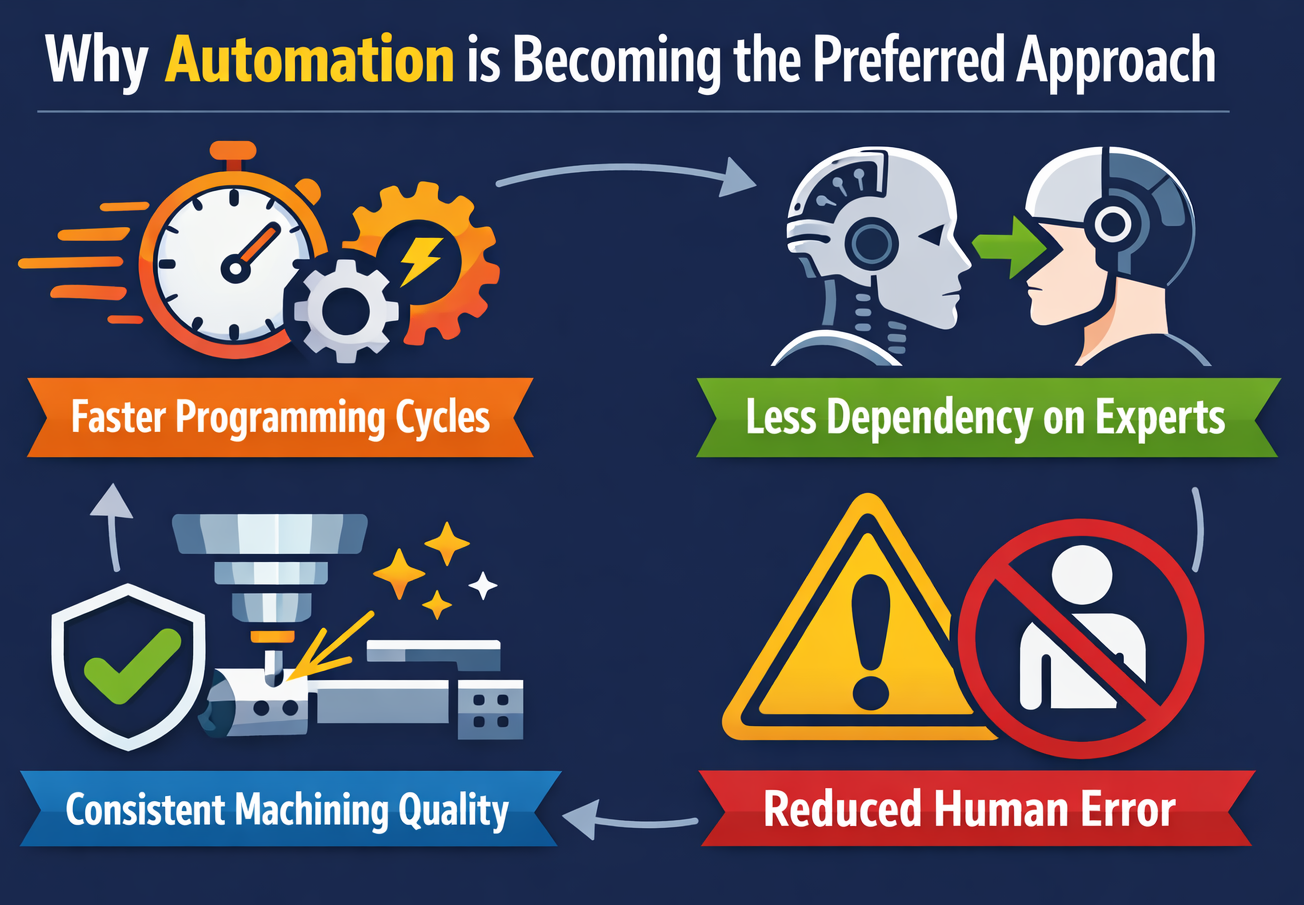

That’s why CAM automation is becoming the way to go:

- Faster programming times

- Less need for highly skilled programmers

- Steady machining quality

- Fewer chances of mistakes

With automation, shops can quickly handle design changes and reach tight deadlines without overworking their teams.

How Automation Saves Time

The first clear win from automation in CAM software is often the time saved.

Here’s where time is saved:

- Automatic toolpath making: Parts that are made over and over can be programmed in minutes, not hours.

- Workflow templates: Machining strategies that work well can be used again for similar parts.

- Less trial and error: Fine-tuned settings reduce test runs.

- Quicker setup changes: Automated setup sheets and records reduce machine downtime.

When these small gains add up, the whole production cycle gets much shorter.

How Automation Helps Lower Cost

Saving time naturally cuts costs, but automation does even more.

CAM automation lowers costs by:

- Cutting down on wasted material from programming errors.

- Reducing machine idle time.

- Lowering rework and scrap rates.

- Letting fewer programmers handle more machines.

By standardizing processes, manufacturers achieve consistent results and better control over production costs.

Manual CAM vs Automated CAM: A Quick Look

| Aspect | Manual CAM Programming | Automated CAM Programming |

|---|---|---|

| Programming Time | High | Low |

| Error Chance | Medium to High | Very Low |

| Consistency | Operator-based | Very Consistent |

| Scalability | Limited | Easy to Grow |

This simple chart shows why more companies are investing in automation for the future.

Real Impact on Shop Floor Output

One of the top benefits of automation is its impact on daily shop-floor work. Machines run more smoothly, operators experience fewer interruptions, and programmers can spend more time on complex tasks rather than tedious work.

Automation also helps keep processes steady, which is great when many programmers or shifts are involved. Everyone uses the same proven machining steps, reducing differences and improving output.

Why Mechman Solution Focuses on Smart Automation

At Mechman Solution, automation should be helpful, not complex to use. The point is to help people, not replace them, with better tools. By effectively using CAM automation, manufacturers can improve their productivity while retaining complete control over machining decisions.

When used correctly, automation becomes a reliable helper, quietly working in the background while teams focus on new ideas and quality. Our solutions aim to address the real problems on the manufacturing shop floor and help improve the business. We provide methods to enhance workflows, shorten task completion time, and maintain programming consistency.

FAQs

1. Does automation mean we don’t need skilled programmers?

No. Skilled programmers are still a must-have. Automation just cuts down on tedious work, letting experts spend more time on complex machining plans and problem-solving.

2. Is automation complex to get going?

Most modern CAM software lets you add automation slowly. You can start with simple templates and add more as your team gets used to them.

3. Can automation handle parts that are custom or complex?

Yes. While automation is great for repetitive tasks, it can also handle complex steps by using improved plans and reducing setup time.

Contact Us

📞 +91 99137 89065