Gujarat has become a leading manufacturing center in India, excelling in areas like precision engineering, automotive parts, tooling, and production led by micro, small, and medium enterprises (MSMEs). Modern CNC operations involve more than just programming machinery. They demand complete platforms that encourage teamwork, automation, and precision. Manufacturers are adopting Fusion 360 CNC in Gujarat to integrate CAD (computer-aided design) and CAM (computer-aided manufacturing), thereby maintaining control over quality, deadlines, and costs.

Understanding the Path from Design to Production

The standard CNC process often involves separate tools for design, modeling, toolpath generation, and production. This separation can result in data loss, rework, and delays. Fusion 360 addresses these problems by providing a single, unified digital space.

Typical steps include:

- Coming up with concepts and creating 3D product designs

- Checking engineering and making changes

- Creating CNC machine toolpaths

- Simulating and verifying processes

- Carrying out production

- Revising designs based on feedback

Having all these steps in one place gives manufacturers speed and clarity throughout the entire product lifecycle.

How Fusion 360 Makes CNC Manufacturing Easier

Fusion 360 combines CAD, CAM, CAE (computer-aided engineering), and data management into a single cloud-based platform. This setup is a direct assist to Gujarat manufacturers who handle different jobs, batch productions, and custom parts.

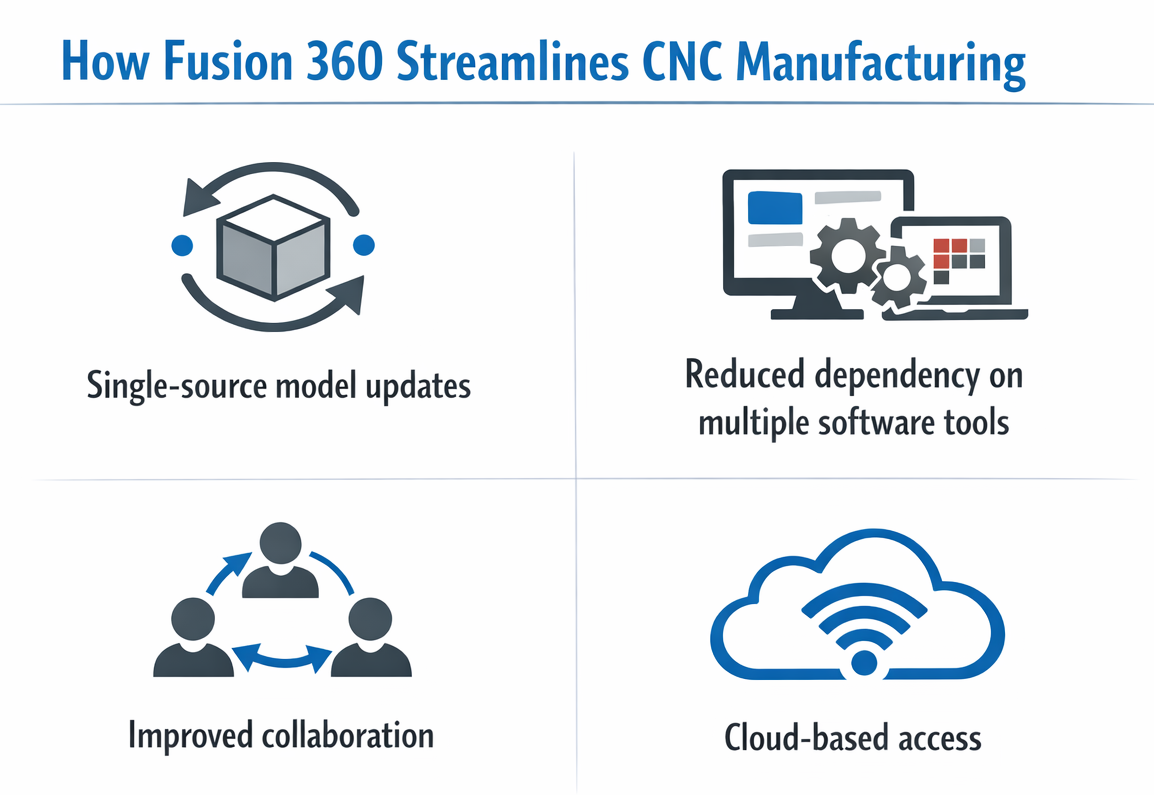

Key processes to improve include:

- Single-source model updates: Any design change automatically updates the machining procedures, without requiring the recreation of files.

- Reduced dependency on multiple software tools: Designers and CNC programmers use the same platform.

- Better teamwork: Teams involved in design, production, and quality control can access the same data.

- Access via the cloud: Work can be checked or changed from anywhere, avoiding problems with different file versions.

These features help manufacturers expand efficiently while maintaining consistent production.

Role of Fusion 360 in CNC Programming Efficiency

One of Fusion 360’s biggest pluses is its advanced CAM area. It allows 2-axis to 5-axis machining, turning, and mill-turn operations.

CNC programming benefits include:

- Automated creation of toolpaths

- Built-in machining plans

- Post-processors for main CNC controllers

- Collision detection and simulation

- Less programming time

With simulation, machine operators can identify errors before running jobs on the shop floor, saving materials and machine time. This is especially helpful for job shops and MSMEs in Gujarat, where downtime directly hits profits.

Improving Accuracy and Quality Control

Precision is essential in industries like automotive, engineering parts, and industrial equipment production. Fusion 360 helps maintain accuracy through digital checks and simulations before actual machining.

Quality improvements include:

- Toolpath checks

- Simulation of material removal

- Modeling that considers tolerances

- Consistent geometry references

- Fewer manual recalculations

By digitally checking processes, manufacturers confirm reliability and accurate dimensions across all batches.

Supporting Customization and Rapid Prototyping

Manufacturers today frequently handle small batches, customized orders, or designs that change quickly. Fusion 360 CNC in Gujarat permits changes without disrupting production processes.

Positives for prototyping and customization:

- Quicker design changes

- Instant CAM updates

- Easy comparison of design versions

- Fast turnaround for customer approvals

This makes Fusion 360 CNC in Gujarat particularly useful for industries that serve varied customer needs and tight delivery schedules.

| Area of Impact | Practical Advantage |

|---|---|

| Job Estimation | Faster cost and time planning before production |

| File Handling | Centralized storage reduces version confusion |

| Machine Compatibility | Supports multiple CNC machine types |

| Process Visibility | Precise tracking of design-to-machining stages |

| Scalability | Suitable for both small and growing manufacturers |

Conclusion

In today’s competitive manufacturing world, efficiency, accuracy, and the ability to adapt determine long-term success. Manufacturers in Gujarat are increasingly adopting digital tools that bring together design and production processes under a single platform.

By adopting Fusion 360 CNC in Gujarat, businesses can streamline processes, reduce operational pressure, and respond faster to market needs. The ability to smoothly transition from design to machining enables manufacturers to maintain quality as production grows.

FAQs

1. Is Fusion 360 a good pick for small CNC workshops in Gujarat?

Yes, it suits small and large workshops because of its design-to-machining process and its ease of learning.

2. Can Fusion 360 handle both milling and turning tasks?

Yes, it handles milling, turning, and multi-axis machining on the same platform.

3. Does Fusion 360 contribute to lowering CNC production errors?

Yes, built-in simulation and inspection tools help find problems before machining, reducing costly errors.

Contact Us

📞 +91 99137 89065