Professionals can design and build with accuracy thanks to Autodesk‘s CAD/CAM tools portfolio, but picking the correct training route is essential for career success. Depending on your objectives, Fusion 360 and PowerMill offer different solutions for design and production demands. This article guides you toward the ideal professional path by assisting you in choosing between Fusion 360 vs PowerMill training, a key decision for anyone pursuing excellence in modern manufacturing.

What Is Fusion 360?

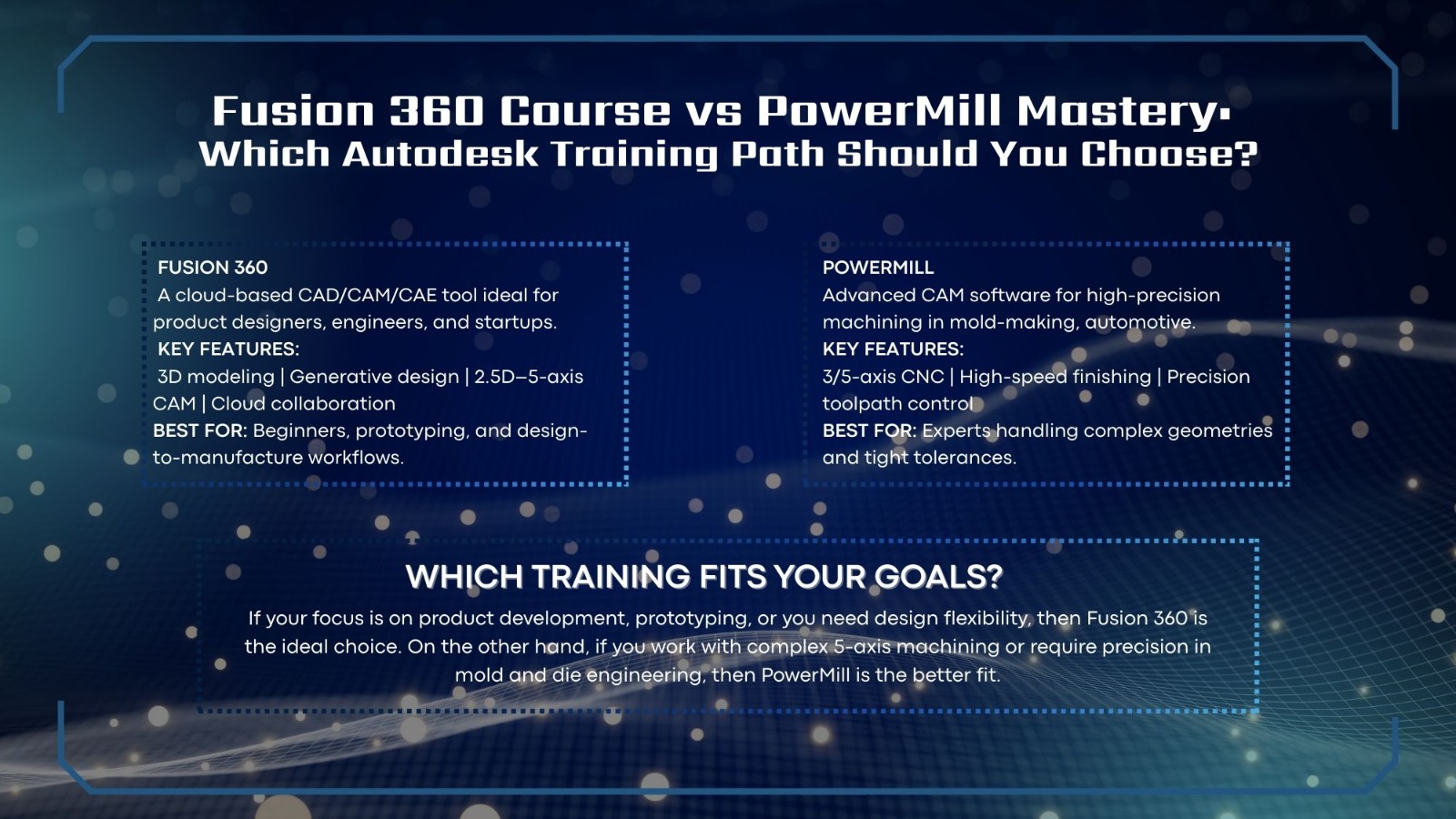

A cloud-based, integrated CAD/CAM/CAE platform, Fusion 360 is perfect for small production teams, mechanical engineers, and product designers. It provides generative design, parametric and freeform modeling, integrated CAM for 2.5D to simple 5-axis machining, and powerful simulation tools. It is ideal for startups and product development because its cloud collaboration function facilitates smooth teamwork. Fusion 360’s flexible training options and beginner-friendly learning curve make it suitable for design-to-manufacture processes and accessible to novices.

What Is PowerMill?

PowerMill is a high-end CAM software designed for intricate surface machining in sectors including mold-making, automotive, and aerospace. It delivers accuracy for complex products by excelling in high-speed finishing, sophisticated 3-axis and 5-axis CNC methods, and unique toolpath control. Toolmakers and die/mold engineers rely on it because of its versatility in handling intricate surfaces and massive components. Its higher learning curve, however, requires specialized training, particularly for individuals who want to become experts in precision machining.

Training Goals—Which One Matches Yours?

Your goals will determine the type of training you choose. With its prototype and product development capabilities, Fusion 360 is perfect for concentrating on end-to-end design-to-manufacture processes. It works well for small teams and startups that require flexibility. PowerMill, on the other hand, is the preferred choice for those who need extensive control over toolpaths and machine behavior; it is ideal for job shops and manufacturing premium parts. PowerMill’s sophisticated CAM capabilities are unparalleled if your task requires intricate geometry and precise tolerances.

Choosing between Fusion 360 vs PowerMill depends heavily on your desired expertise level and sector focus, making it essential to align your training with your project requirements.

Career Opportunities & Industry Demand

Jobs in consumer product innovation, freelance CAD, and product design are all made possible by Fusion 360 training. In the United States, certified professionals earn between $60,000 and $80,000 a year as design engineers or product developers. Expertise in PowerMill is in great demand in the die/mold, automotive, and aerospace industries, leading to positions like production engineer or CNC programmer, which pay between $75,000 and $100,000 or more. Both Autodesk certifications improve employment opportunities, while PowerMill’s specialized talents are highly valued in specialized fields.

Cost & Accessibility

Fusion 360 training is reasonably priced, with membership at $500/year and free access for entrepreneurs and students (limited features). All you need is a computer and an internet connection to take its beginner-friendly, self-paced online courses. Targeting businesses, PowerMill is expensive (sometimes thousands of dollars a year) and usually requires on-site or instructor-led training, making it appropriate for specialist facilities. When comparing Fusion 360 vs PowerMill, it’s clear that Fusion 360 is widely available and more accessible, while PowerMill’s complexity and expense are appropriate for high-investment, precision-focused settings.

What’s the Right Path for You?

Make a decision using this checklist:

- Current Role: Fusion 360 is helpful for designers or novices, whereas PowerMill is necessary for CAM programmers.

- Industry Sector: Fusion 360 is preferred by consumer goods or startups, whereas PowerMill is needed in the mold-making or aerospace industries.

- Project Complexity: Fusion 360 works well for simple prototypes, while PowerMill is needed for complex 5-axis components.

- Workplace Culture: Machine shops like PowerMill, whereas design offices tend to choose Fusion 360.

Comparison Table: Fusion 360 vs PowerMill

| Aspect | Fusion 360 | PowerMill |

|---|---|---|

| Focus | Design-to-manufacture | Advanced CAM |

| Machining | 2.5D to basic 5-axis | Advanced 3/5-axis |

| Learning Curve | Beginner-friendly | Expert-level |

| Cost | Affordable/Free for students | Premium |

| Best For | Startups, prototyping | Aerospace, mold-making |

In Conclusion

For novices and those looking for a versatile, integrated CAD/CAM solution for small-scale manufacturing and prototyping, Fusion 360 training is perfect. It is an excellent place to start because of its low cost and simplicity. PowerMill’s accuracy and control are ideal for experts working on intricate, valuable parts in demanding sectors. To make the best decision, evaluate your job, industry, and project requirements. The Fusion 360 vs PowerMill decision ultimately depends on your ambition, whether you want accessible, broad-scope functionality or specialized, high-precision control.

The moment to take action is now, regardless of your goals: future-proof your workshop, optimize complicated toolpaths, or reduce programming time.

Mechman Solution, your reliable Autodesk partner, offers a free demo on how Fusion 360 or PowerMill training will help you achieve your professional objectives.

Begin your path to CNC machining that is intelligent, effective, and scalable. One toolpath at a time, let’s construct the manufacturing of the future.

👉 Contact us today to book a free demo or training consultation.

📩 mechmansolution@gmail.com | 📞 +91 99137 89065 | 🌐 www.mechmansolution.com

Also Read: Autodesk Fusion 360 vs PowerMill: Which CAM Software Is Best For Complex Machining?