The foundation for modern machining is Computer-Aided Manufacturing or CAM software, which allows for accuracy and speed in intricate manufacturing. With unparalleled efficiency, Autodesk PowerMill is a premier CAM solution reinventing high-speed machining (HSM). This article examines how PowerMill outperforms rivals and boosts efficiency in mold-making, automotive, and aerospace sectors.

What is High-Speed Machining?

High spindle speeds and feed rates are used in high-speed machining to cut quickly while maintaining accuracy and efficiency. HSM is widely used in mold-making, automotive (such as engine components), and aerospace (such as turbine blades). It improves surface finishes, shortens cycle times, and prolongs tool life. It is essential for competitive production because it can handle complicated geometries with little setup.

Overview of Autodesk PowerMill

PowerMill is a powerful CAM software intended for advanced manufacturing. It excels in 5-axis and high-speed machining and has important features such as multi-axis support for complex components, adaptive toolpaths for effective material removal, and strong simulation tools to avoid mistakes. Because of these features, PowerMill is a great option for manufacturers looking for speed, accuracy, and dependability in HSM operations.

Efficiency Enhancements in PowerMill for High-Speed Machining

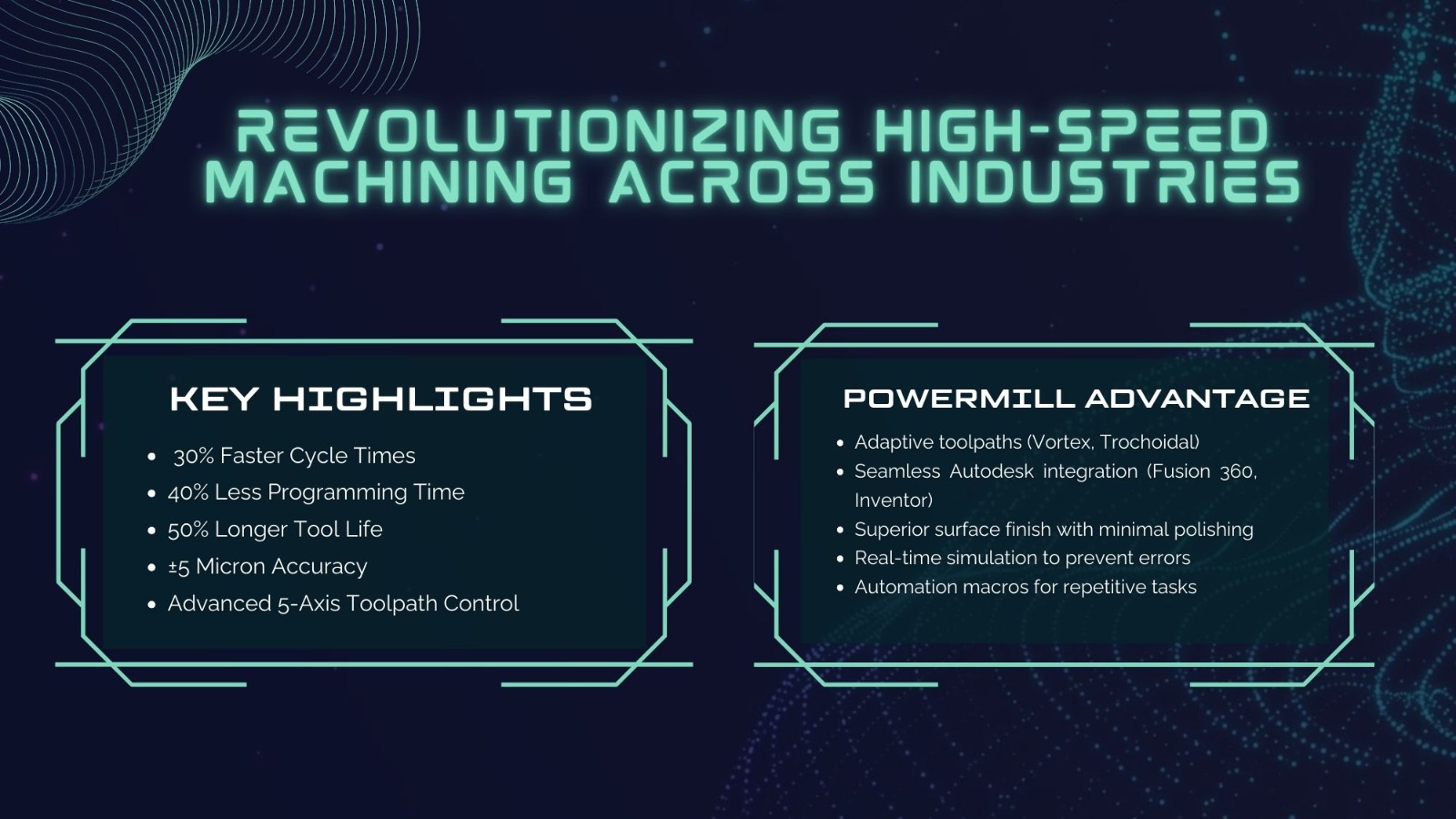

- Advanced Toolpath Strategies: Vortex and trochoidal milling are two examples of PowerMill’s adaptive toolpaths, which optimize material removal rates while reducing tool wear. These techniques ensure clean, effective cuts by reducing machine time by up to 30% compared to conventional procedures.

- Automation Features: Automating repetitive operations, custom macros, and templates reduces setup times and human error. Batch processing makes rapid programming of several parts possible, improving uniformity in high-volume manufacturing.

- Integration with Autodesk Tools: PowerMill simplifies design-to-manufacturing processes by integrating easily with Inventor and Fusion 360. Unlike many independent CAM software, this link speeds up project deadlines and lowers data translation mistakes.

PowerMill’s Cutting-Edge Features Compared to Other CAM Software

- Toolpath Optimization: PowerMill’s adaptive toolpaths dynamically adapt to geometry, minimizing vibrations and air-cutting, contrasting to rivals like Siemens NX and Mastercam. This outperforms static toolpath techniques in terms of cycle durations and tool stress.

- Surface Finish Quality: PowerMill produces excellent surface finishes with less polishing because of its optimized cutting techniques, which include constant Z and flowline finishing. To attain similar outcomes, competitors frequently need to make further manual modifications.

- Multi-axis Support: PowerMill’s strong 5-axis capabilities provide accurate tool axis control and can easily handle complicated geometries. The HSM efficiency of many CAM softwares, such as GibbsCAM, is limited by their inability to handle simultaneous multi-axis machining.

- Simulation Features: PowerMill’s sophisticated simulation detects collisions and gouging before machining starts, giving real-time feedback. Although programs like Esprit provide simulation, PowerMill’s use of machine kinematics guarantees greater accuracy.

Real-World Applications and Success Stories

Using PowerMill’s 5-axis toolpaths, an aerospace company could process titanium turbine blades with ±5-micron tolerances and a 25% decrease in cycle time. PowerMill’s automation helped a mold-making company improve delivery schedules by reducing programming time by 40%. A supplier to the automotive industry reported improved surface quality and a 50% longer tool life, which decreased rework expenses. These results demonstrate PowerMill’s capacity to produce quantifiable efficiency increases.

Comparing PowerMill’s Cost Efficiency with Other CAM Software

PowerMill’s business focus is reflected in its premium pricing, but its long-term cost-effectiveness is unparalleled. Optimized toolpaths decrease tool wear and machining time, lowering operating expenses. For high-volume operations, for instance, a 30% decrease in cycle time results in thousands of dollars in savings annually. Even if competitors like Mastercam are initially less expensive, their less effective toolpaths and manual rework frequently result in greater expenses, making PowerMill a better investment.

User Experience: PowerMill’s Intuitive Interface vs Competitors

Despite its complexity, PowerMill’s interface is simplified for more experienced users, offering simple toolpath visualization and customized processes. Once mastered, PowerMill provides a more seamless experience than Mastercam’s antiquated architecture or Siemens NX’s disorganized interface. Autodesk’s vast training tools accelerate new users’ learning curve, surpassing rivals’ sometimes inadequate help, including tutorials, forums, and Mechman Solution’s courses.

The Future of High-Speed Machining and PowerMill’s Role

Emerging technologies like Industry 4.0, digital twins, and AI-driven machining alter HSM. With regular upgrades incorporating predictive analytics and IoT connectivity, PowerMill is well-positioned to take the lead. Its capacity to supply accurate toolpath data into digital workflows makes it a key component of smart manufacturing, surpassing rivals who are more sluggish in embracing these advancements.

In Conclusion

Autodesk PowerMill’s sophisticated toolpaths, automation, and multi-axis capabilities redefine efficiency in high-speed milling. It outperforms rivals like Mastercam and Siemens NX by cutting cycle times, improving surface quality, and lowering expenses. PowerMill is the best CAM solution for producers who value accuracy and speed, boosting output in the current competitive environment.

Whether you aim to cut programming time, optimize complex toolpaths, or future-proof your workshop, act now.

Book a free demo with Mechman Solution—your trusted Autodesk partner. Get personalized insights on how PowerMill fits your production needs.

Start your journey toward innovative, efficient, and scalable CNC machining. Let’s build the future of manufacturing—one toolpath at a time.

👉 Contact us today to book a free demo or training consultation.

📩 mechmansolution@gmail.com | 📞 +91 99137 89065 | 🌐 www.mechmansolution.com