Gujarat has long been among India’s most developed states in terms of industry. It’s well-known for its strong network of small- and medium-sized businesses, large factories, and enterprises focused on exporting goods. Lately, the use of digital methods has become a significant factor in growth, and CAD/CAM software in Gujarat is playing a key role in changing how manufacturers design, plan, and make parts with greater accuracy and speed.

From car-making areas in Sanand to engineering centers in Rajkot and Ahmedabad, manufacturers are using new digital tools to stay competitive in a global market that demands precision, efficiency, and reliability.

Gujarat’s Manufacturing Network and Why Digital Tools Are Needed

Gujarat is a significant part of India’s manufacturing output in areas like:

- Automotive and auto components

- Making molds and dies

- Precision engineering

- Plane parts

- Electric and electronic devices

- Heavy engineering

- Machine tools

Because there’s more competition and higher quality needs, old ways of designing and making things aren’t good enough anymore. Manufacturers now need comprehensive digital solutions that integrate design, copying, and machining into a single process.

That’s where CAD/CAM technologies are necessary.

How CAD/CAM Software Changes the Game

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software work together to create a seamless connection between design and manufacturing. They reduce manual work and help make more informed decisions throughout the production process.

Main benefits include:

- Faster product creation times

- Fewer design and machining mistakes

- Better use of CNC machines

- More consistent and reliable results

- Less waste of material

- Improved surface quality

Because of this, many industries are quickly investing in CAD/CAM software in Gujarat to bring their production methods up to date.

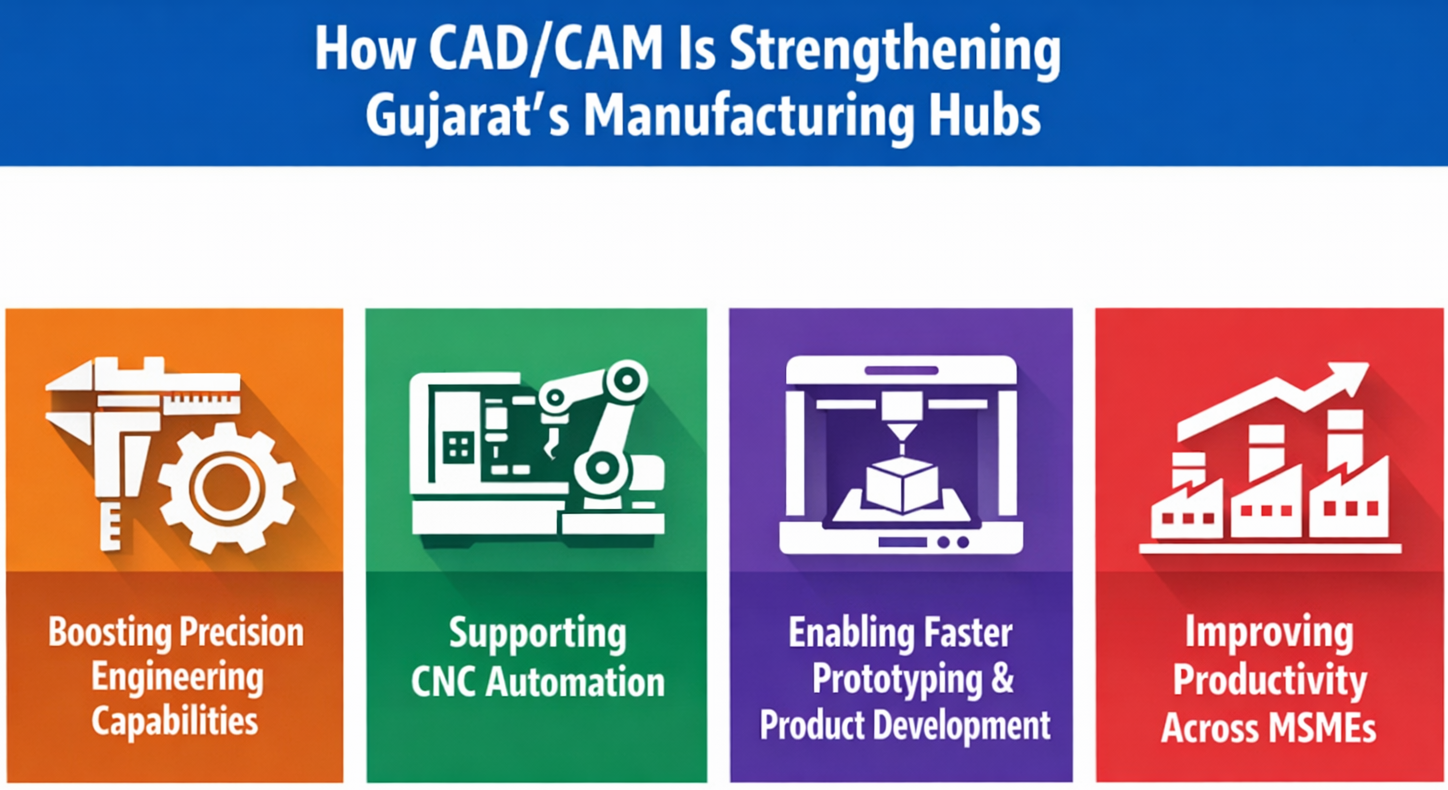

How CAD/CAM Is Making Gujarat’s Manufacturing Centers Stronger

Boosting Precision Engineering Skills

Precision engineering relies heavily on accuracy down to the micron level.CAD/CAM software in Gujarat enables manufacturers to copy tool movements, verify designs, and correct errors before any actual machining. This ensures better dimensional accuracy and improved surface finishes.

Supporting CNC Automation

Because more CNC machines are being used, CAM software is key in:

- Creating improved G-code

- Automating toolpath strategies

- Cutting down on setup time

- Making machines work better

This automation helps manufacturers produce more without lowering quality.

Making Prototyping and Product Creation Faster

Design changes that used to take weeks can now be done in days. CAD tools enable engineers to quickly modify models, test virtual setups, and prepare designs for manufacturing.

Boosting Output Across Small and Medium-Sized Businesses

Small and medium-sized businesses are the foundation of Gujarat’s industry network. CAD/CAM use helps these businesses compete with bigger companies by:

- Needing less skilled manual drafting

- Reducing the amount of rework

- Increasing output

- Providing steady quality

Traditional vs Digital Manufacturing Support

Here’s a quick comparison between traditional and digital manufacturing support:

| Aspect | Traditional Methods | CAD/CAM- Approach |

|---|---|---|

| Design changing speed | Slow and manual | Quick and digital |

| Error detection | After machining | Before production |

| Skill dependency | Highly operator-dependent | Process-driven |

| Documentation | Paper-based | Digital and reusable |

| Scalability | Limited | High and flexible |

CAD/CAM solutions help industries increase output, correctness, and competitiveness while reducing mistakes and wasted effort.

The Future of Manufacturing in Gujarat

Gujarat’s dream of becoming a world manufacturing center goes well with digital engineering technologies. As factories move toward intelligent manufacturing, CAD/CAM software will remain the primary link between design innovation and high-quality production. With improvements in AI tool movement, copy-based machining, and cloud-based teamwork, manufacturers will have even more control over quality, price, and delivery times.

As manufacturing centers continue to evolve, CAD/CAM software in Gujarat will remain a key driver of innovation and sustained industry growth. By investing in the right tools and knowledge, manufacturers can confidently prepare for the future of innovative, connected production.

FAQs

1. Which industries in Gujarat get the most help from CAD/CAM software?

Industries such as automotive, molds & dies, aircraft, precision engineering, medical devices, and heavy engineering benefit significantly from CAD/CAM use.

2. Is CAD/CAM software suitable for small manufacturing shops?

Yes, even small and medium-sized businesses can benefit from greater accuracy, faster production times, and reduced manual work.

3. Does CAD/CAM software work with CNC machines?

Yes, CAM software generates CNC machine programs and optimizes tool movements for efficient, accurate machining.

Contact Us

📞 +91 99137 89065