The need for CNC machining’s accuracy, speed, and automation has never been greater in the fast-paced production environment of today. Five-axis CNC machining, in conjunction with sophisticated CAM software for 5 axis programming, has revolutionized the industry by providing unparalleled accuracy and efficiency as industries push the limits of innovation. This article examines how CAM software for 5 axis programming revolutionizes production for competitive manufacturing by transforming five-axis programming.

Understanding Five-Axis CNC Machining

X, Y, Z, and two rotational axes (A and B) are the five axes that a cutting tool moves across simultaneously in five-axis CNC machining. Five-axis machining is more flexible and precise than three-axis machines, which work in three linear directions, or four-axis setups, which add one rotational axis. This feature is perfect for complex components since it enables the tool to approach the workpiece from almost any angle. Five-axis machining is essential to the production of complex parts like engine components, surgical implants, turbine blades, and molds and dies for automotive, aerospace, and medical device manufacturing.

Role of CAM Software for 5 Axis Programming

Multi-axis CNC machining relies on Computer-Aided Manufacturing (CAM) software. It creates toolpaths that specify the movement of the tool by converting CAD (Computer-Aided Design) models into exact instructions for CNC machines. Because multi-axis movements are so complex, CAM software for 5 axis programming is essential for five-axis machines. It is an essential tool for manufacturers looking to increase productivity since it makes programming easier, guarantees design and execution consistency, and streamlines the machining process.

Key Benefits of CAM Software for Five-Axis CNC

a. Enhanced Machining Efficiency

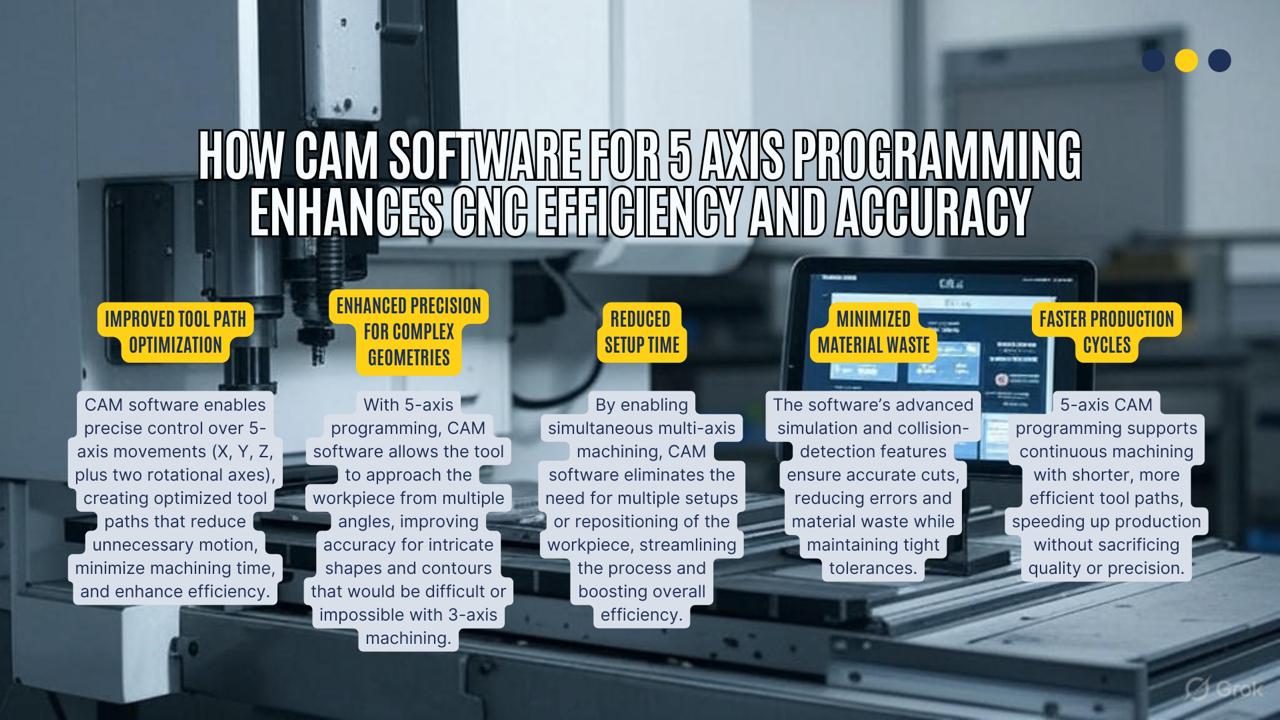

Through the creation of faster toolpaths and the reduction of cycle times, CAM software greatly increases efficiency. By optimizing roughing and finishing procedures, it enables machines to accomplish work in fewer passes and remove material more quickly. This efficient method gives enterprises a competitive edge by reducing downtime and speeding up production.

b. Unmatched Precision and Accuracy

In five-axis machining, accuracy is crucial, and CAM software provides it with sophisticated capabilities like collision avoidance and detection. It avoids expensive mistakes by simulating tool actions, guaranteeing the safety of both the tool and the workpiece. Furthermore, even on the most complex designs, consistent accuracy is ensured by precise control over tool orientation and placement.

c. Complex Geometry Handling

The capacity of CAM software to handle complex geometry with ease is one of its most notable benefits. It makes it possible to machine products with deep cavities, complicated curves, and undercuts—features that are difficult or impossible to achieve with three-axis systems. It guarantees the perfect implementation of complex designs and minimizes human error by doing away with manual repositioning.

d. Reduction in Setup Time and Manual Intervention

CAM software significantly reduces setup times. Operators can see the entire process in advance thanks to its comprehensive simulations and automated toolpath development. By eliminating the need for several fixtures and manual adjustments, five-axis machining allows for single-setup procedures for multi-sided components, reducing time and labor costs.

e. Improved Tool Life and Surface Finish

Optimized CAM toolpaths allow for smoother tool movements, which prolong tool life and minimize wear. Additionally, the software adjusts cutting parameters to produce better surface finishes while reducing the need for extra polishing. This dual advantage improves cost-effectiveness while producing excellent results that satisfy exacting industrial standards.

Why Choose Autodesk PowerMill and FeatureCAM?

Five-axis programming is enhanced by the industry-recognized CAM products PowerMill and FeatureCAM from Autodesk. PowerMill is a leader in complex surface finishing and high-speed machining, providing reliable toolpath methods for applications requiring accuracy. The automatic feature detection of FeatureCAM, on the other hand, significantly reduces programming time by rapidly detecting machinable features from CAD models. Leading CAD platforms are perfectly integrated with both tools, guaranteeing a seamless workflow from design to manufacturing. These solutions are used by manufacturers all over the world because of their dependability and adaptability.

Mechman Solution: Your Partner in Precision

Mechman Solution is dedicated to empowering manufacturers throughout India as an authorized Autodesk distributor and training partner. Businesses may fully utilize PowerMill and FeatureCAM with Mechman’s individualized support and expert-led courses. Leaders in the industry trust Mechman because of their track record of improving production capabilities and their ability to provide specialized guidance and practical training to guarantee the smooth implementation of these cutting-edge technologies.

Key Takeaway

By enhancing productivity, accuracy, and adaptability, CAM software for 5 axis programming transforms five-axis CNC machining and is a vital tool for contemporary manufacturing. CNC performance is now at a new level thanks to technologies like Autodesk PowerMill and FeatureCAM, which can reduce cycle times and master complex geometries. Mechman Solution is a trustworthy partner that offers the know-how and technology required to improve your production capabilities. CAM software for 5-axis programming and professional assistance are essential for manufacturers who want to stay ahead of the competition.

Are you prepared to advance your CNC machining skills? For professional Autodesk PowerMill and FeatureCAM training, individualized consultancy, and accuracy-driven software solutions, get in contact with Mechman Solution.

Contact us today to book a free demo or training consultation.

📩 mechmansolution@gmail.com | 📞 +91 99137 89065 | 🌐 www.mechmansolution.com

Also Read: Why PowerMill And FeatureCAM Are Among The Best CAD CAM Software In India?