CNC (Computer Numerical Control) programming is critical in modern manufacturing, driving precision and efficiency in aerospace, automotive, and medical device production. As demand for skilled CNC programmers grows, choosing the right training course is essential to align your skills with career aspirations. With numerous options available, from beginner-friendly to advanced certifications, this guide explores key factors to consider when selecting a CNC programming course, ensuring it meets your professional goals.

Understand Your Career Objectives

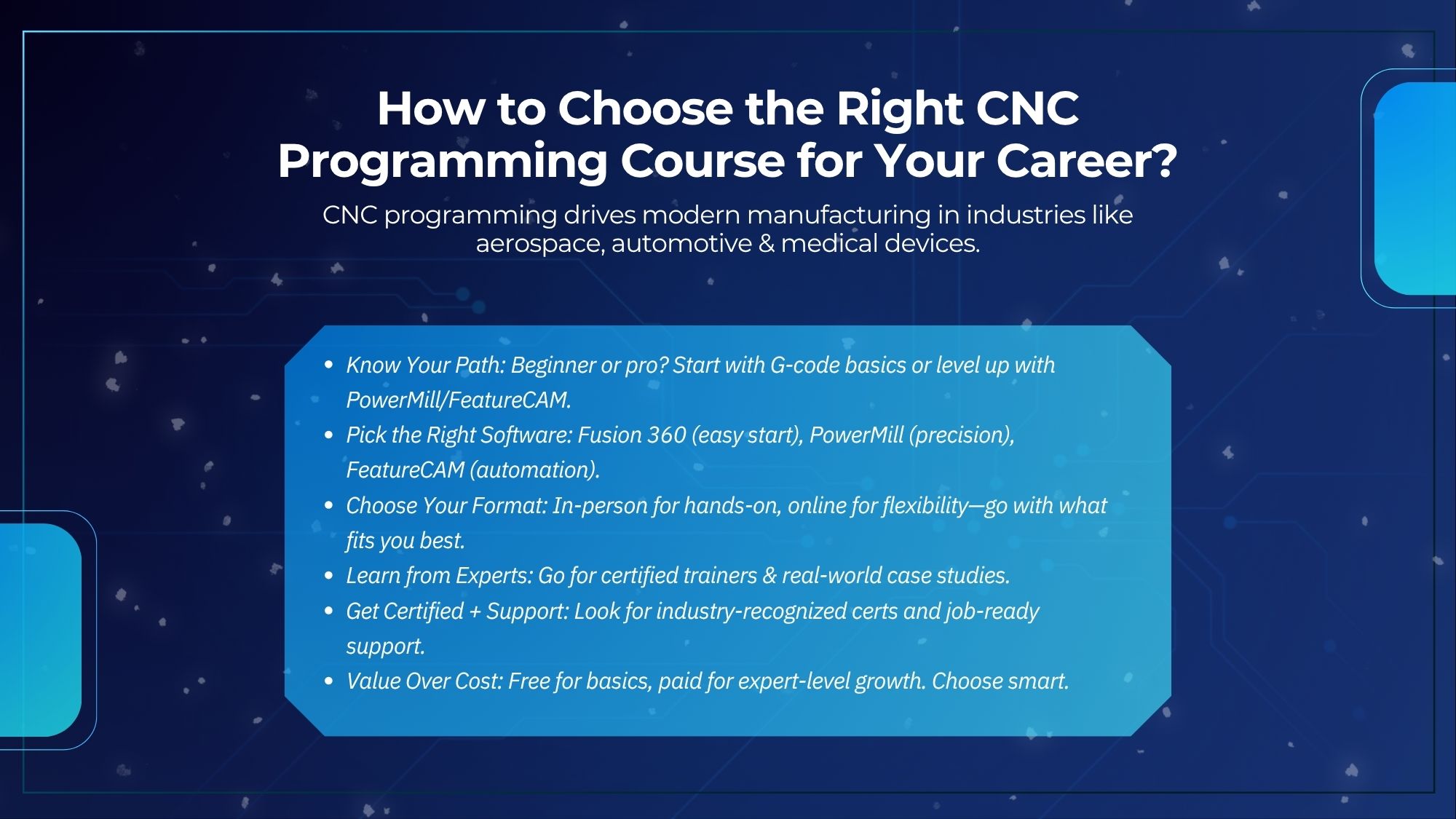

Before enrolling in a CNC programming course, clarify your career goals. Are you aiming to become a CNC operator, a programmer for complex 4-axis VMC (Vertical Machining Center) setups, or a CAM (Computer-Aided Manufacturing) software specialist? Each role requires different skills. For instance, operators need hands-on machine knowledge, while programmers focus on software like Autodesk Fusion 360 or PowerMill for toolpath creation.

If you’re a beginner, seek courses that cover foundational skills, such as G-code basics and machine setup. For advanced roles, prioritize training in multi-axis programming or automation integration. Aligning the course with your goals, whether entering the industry or advancing to a lead programmer role, ensures you invest time and resources effectively.

Evaluate Course Content and Software Focus

The course content should match your technical needs and industry demands. Look for programs teaching widely used CAM software like Autodesk Fusion 360, PowerMill, or FeatureCAM, as these tools dominate modern CNC workflows. Fusion 360 is ideal for beginners due to its cloud-based interface and design-to-manufacturing capabilities. PowerMill suits advanced users tackling high-speed, multi-axis machining, while FeatureCAM excels in automation-driven programming.

Check if the course covers practical skills like optimizing Fanuc post processors, simulating toolpaths, or integrating AI for predictive maintenance. Comprehensive curricula should include hands-on projects, such as creating toolpaths for real-world parts, to bridge theory and practice. Ensure the course emphasizes software relevant to your target industry, as aerospace may prioritize PowerMill’s precision, while general manufacturing leans toward FeatureCAM’s efficiency.

Assess Training Delivery and Accessibility

The delivery format of a CNC programming course impacts its effectiveness. Options include in-person workshops, online self-paced modules, or hybrid programs. In-person training offers hands-on machine access, ideal for learning physical setups, but may require travel. Online courses, like Autodesk’s learning paths, provide flexibility and access to cloud-based tools, making them suitable for busy professionals or remote learners.

Consider accessibility features like recorded lectures, interactive simulations, or mobile-friendly platforms. For global teams, cloud-based training with tools like Fusion 360 enables collaborative learning. Evaluate whether the CNC programming course offers ongoing support, such as forums or instructor feedback, to address challenges during complex topics like multi-axis programming or robotic integration.

Check Instructor Expertise and Industry Relevance

Instructor quality is essential when it comes to learning. Be sure to choose courses taught by experienced industry professionals well-versed in CNC programming and CAM software. Professors should be hands-on, experienced users of software such as PowerMill or FeatureCAM and should be aware of industry trends, including those related to AI-infused machining or environmental sustainability. Certifications from Autodesk or other organizations help build credibility.

Industry relevance is equally important. Programs need to be applicable to industry requirements today, and automation, cloud workflow, or environmental approaches to machining should be covered. Be sure to know if the CNC programming course includes projects or case studies representative of industry types, like aerospace or automobile, so that you have experience in real-world situations.

Consider Certification and Career Support

A recognized certification can boost your resume and credibility. Autodesk-certified courses for Fusion 360, PowerMill, or FeatureCAM validate your skills and are valued by employers. Verify if the course offers a certificate upon completion and whether it’s recognized in your target industry.

Career support is another factor. Some programs provide job placement assistance, resume-building workshops, or networking opportunities with manufacturing firms. Courses that connect you with industry partners or offer guidance on optimizing Fanuc post processors for specific machines can give you a competitive edge in the job market.

Balance Cost and Value

Price is a fair issue, but never should it take precedence over value. Compare course cost against course breadth of content, teacher experience, and certification benefit. Beginning courses available for a nominal cost or even free, like those on Autodesk’s learning site, are appropriate for neophytes but would be superficial for skilled positions. Expensive, hands-on training or personally customized feedback courses may be justifiable in a budget, depending on your goals.

Start Your CNC Journey with Mechman Solutions

Looking to advance your CNC programming experience? Discover how training in Autodesk FeatureCAM and PowerMill can transform your career.

Mechman Solutions, your trusted Autodesk partner, offers tailored training to meet your unique manufacturing goals.

Book a free demo or training consultation today and take the first step toward more innovative, more efficient CNC programming. Let’s shape your future in manufacturing, one toolpath at a time.

👉 Contact us today to book a free demo or training consultation.

📩 mechmansolution@gmail.com | 📞 +91 99137 89065 | 🌐 www.mechmansolution.com

Also Read: Exploring the Latest Trends in CNC Programming: AI, Automation, and More