In manufacturing, Computer Numerical Control (CNC) machines have changed how parts are produced. If a workshop has several machines from different sellers, keeping their programs consistent can quickly become disorganized. That’s why CNC programming standardization is essential. Standardizing programs saves time, improves accuracy, reduces mistakes, and keeps everything running smoothly in the workshop.

Why Standardization Is Important

Think about this: there are three different CNC machines-one from Haas, one from Mazak, and one from Fanuc. Each one has its own way of doing things, and the programs for the same part vary slightly from machine to machine. Without standardization:

- Workers have to spend more time understanding the specific codes for each machine.

- Mistakes happen more often because the setups are different.

- Fixing problems and keeping things running becomes more complicated.

By using CNC programming standardization, a common method is created, making the process more predictable and easier to manage.

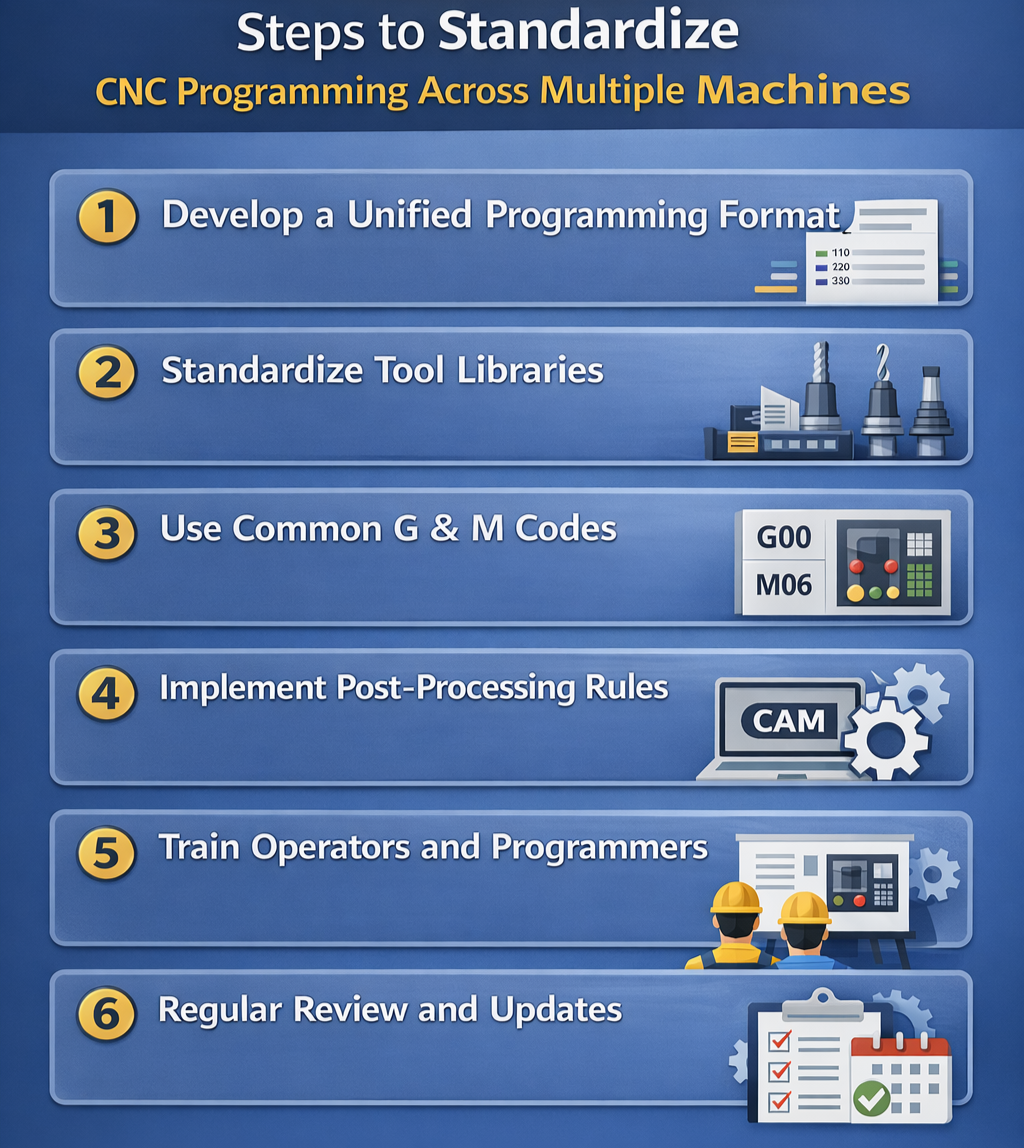

How to Standardize CNC Programming for Different Machines

1. Create a Common Programming Format

Begin by creating a standard form for all CNC programs. This should have:

- A header with the part number, revision, and material

- A tool list with tool numbers that are the same for all machines

- Standard coordinate systems and zero points

Using a consistent format helps anyone reading the program understand it, regardless of the type of machine it is for.

2. Make Tool Libraries Standard

One of the most significant problems with workshops that use different machines is that their tool libraries differ. By creating a central tool library, it’s ensured that:

- Tool numbers are the same across all machines

- Tool offsets are stored in a single location

- It is easier to move programs between machines

A table that shows:

| Tool Type | Tool Number (Standard) | Typical Use |

|---|---|---|

| End Mill | T01 | Pocket milling |

| Drill | T02 | Through holes |

| Face Mill | T03 | Surface finishing |

| Tap | T04 | Threading |

3. Use Common G and M Codes

Different CNC machines often use different G and M codes for the same actions. Standardizing the codes used while ensuring they still work across machines reduces confusion.

For example:

- G00 for rapid moves

- G01 for linear interpolation

- M06 for tool change

Having a reference chart that workers can easily see helps keep things consistent.

4. Implement Post-Processing Rules

If CAM software is used, setting the same post-processing rules ensures that the generated code behaves consistently across all machines. Think about:

- Consistent formatting for spindle speed and feed rate

- Standard starting and stopping codes for cycles

- A typical plan for canned cycles

5. Teach Operators and Programmers

Even with the standards, people can still make mistakes. Regular training sessions for workers and programmers help ensure they follow standard procedures. Sharing tips and updates to make the standard better over time should be encouraged.

6. Review and Update Regularly

CNC technology changes, and the standards should as well. Regularly review the CNC programming standardization procedures to ensure they remain helpful. Update the forms, tool libraries, and code references when needed.

What Benefits to Expect

By standardizing CNC programming for different machines:

- Programming errors are reduced

- Setups are faster

- Communication between workers is easier

- Fixing problems is easier

- The quality is the same across all machines

Standardization also helps with growth. If new machines are added to the workshop, they can be added quickly without creating a new programming process. Using CNC programming standardization might seem like more work at first, but the long-term advantages are very significant. From fewer errors to smoother processes, the workshop will run more productively, regardless of how many machines are in use. Start small with forms and tool libraries, then gradually move toward complete standardization; the future and workers will benefit.

FAQs

Q1: Can standardization be used with machines from different brands?

Yes! By focusing on standard codes, tools, and forms, consistency can be maintained even with machines from different companies.

Q2: How often should CNC programming standards be updated?

Standards should be reviewed at least every 6-12 months, or when new tools or machines are added.

Q3: Will standardization slow down programming at first?

There might be a brief learning period at the beginning, but overall it will speed up programming, reduce errors, and make the workshop more efficient.

Contact Us

📞 +91 99137 89065