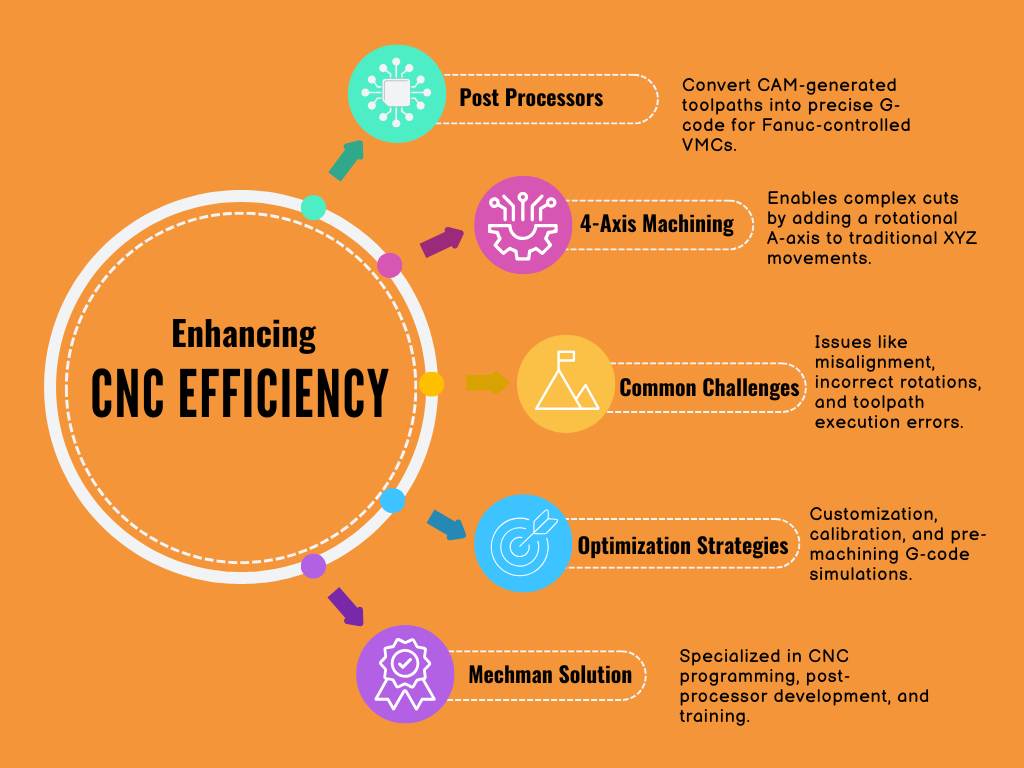

Post-processors are an essential component in CNC machining that converts software design instructions into G-code, which controls a machine’s operation. Optimizing these post processors, especially the Fanuc Post Processor for 4 Axis VMC, is essential to achieving high precision and operating efficiency for 4-axis Vertical Machining Centers (VMC) with Fanuc controllers. A Vadodara-based business that specializes in CNC optimization, Mechman Solution offers the technological know-how required to meet these expectations and assist businesses in streamlining their operations efficiently.

Understanding 4-Axis VMC and Fanuc Post Processors

The workpiece can rotate while being machined thanks to a 4-axis VMC’s rotational A-axis, which complements the conventional X, Y, and Z axes. In sectors like aerospace and automotive, where intricate geometries necessitate cuts from several angles without manual repositioning, this capability is very useful. The Fanuc Post Processor for 4 Axis VMC is essential because it transforms CAM-generated toolpaths into G-code that Fanuc-controlled machinery can correctly understand. When optimized, it guarantees that each action complies with the design objectives, improving output quality and performance.

Common Challenges in 4-Axis CNC Machining

A VMC faces a number of technological challenges when a fourth axis is added. Misalignment is a common problem that results in inaccurate cuts when the rotary axis does not smoothly integrate with the machine’s coordinate system. Directional errors are another frequent issue. For example, the A-axis may rotate clockwise rather than counterclockwise, leading to inefficiencies or defective components. Machinists frequently report cases where simulations appear flawless, but the G-code execution causes misaligned features or tool collisions. These challenges highlight how crucial accurate post-processor setup and equipment configuration are.

Strategies for Optimizing Fanuc Post Processors

Customization is essential for Fanuc Post Processor for 4 Axis VMC optimization in 4-axis machining. This entails modifying variables such as angle settings and axis vectors to correspond with the unique kinematics of the VMC. Determining the proper rotational direction, for instance, guarantees that the machine always moves in the desired direction. Since even small deviations can disrupt the entire process, precise machine calibration and configuration are equally important. A useful strategy that professionals like Mechman Solution frequently use is modeling the G-code before machining. Time and money can be saved by detecting potential problems early on, such as collisions or improper movements.

Mechman Solution’s Approach to CNC Optimization

Renowned for providing professional CNC programming and training services, Mechman Solution is based in Gujarat, India. They use Autodesk PowerMill and Fusion 360 to improve machining operations, and they have more than 150 licenses installed and a clientele of more than 100. Among their services is the creation of custom post-processors for 4-axis VMC configurations, which guarantee smooth integration with specific machine specifications. Although in-depth case studies are not frequently shared, their emphasis on cutting cycle times and increasing accuracy points to a solid track record of effective optimization projects. Their training programs strengthen machinists’ value as technical partners by giving them the ability to manage intricate setups.

Best Practices for Seamless 4-Axis Machining

Following a few best practices is necessary to achieve reliable 4-axis machining.

- A crucial step is to simulate processes before operating the machine so that machinists can spot and fix problems beforehand.

- Consistent performance over time can be maintained by routine maintenance, such as checking the rotary axis for wear or misalignment.

- Another crucial practice is to keep the software and Fanuc Post Processor for 4 Axis VMC updated, as these updates frequently contain fixes and improvements that increase functionality.

- Furthermore, keeping thorough records of machine settings and configurations that work simplifies troubleshooting and subsequent operations.

To guarantee that customers can maintain high standards on their own, Mechman Solution places a strong emphasis on these practices in its training.

In Conclusion

Fanuc Post Processor for 4-Axis VMC optimization has observable advantages, including increased accuracy, fewer mistakes, and quicker production cycles. But because of its technical complexity, this procedure frequently calls for professional advice. Because of their expertise in CNC optimization, Mechman Solution is a reliable partner for firms dealing with these issues. Businesses may improve the efficiency and quality of their products by utilizing their services to hone their machining processes. Professional assistance may have a big impact on those who want to improve their CNC operations.

Contact Mechman Solution to arrange a free demo or training consultation for customized assistance in improving your CNC systems:

📩 mechmansolution@gmail.com | 📞 +91 99137 89065 | 🌐 www.mechmansolution.com

Reach your CNC optimization objectives by utilizing professional solutions.

Also Read: Best Free Software for 5-Axis CNC Programming: What Mechman Solution Recommends for Beginners