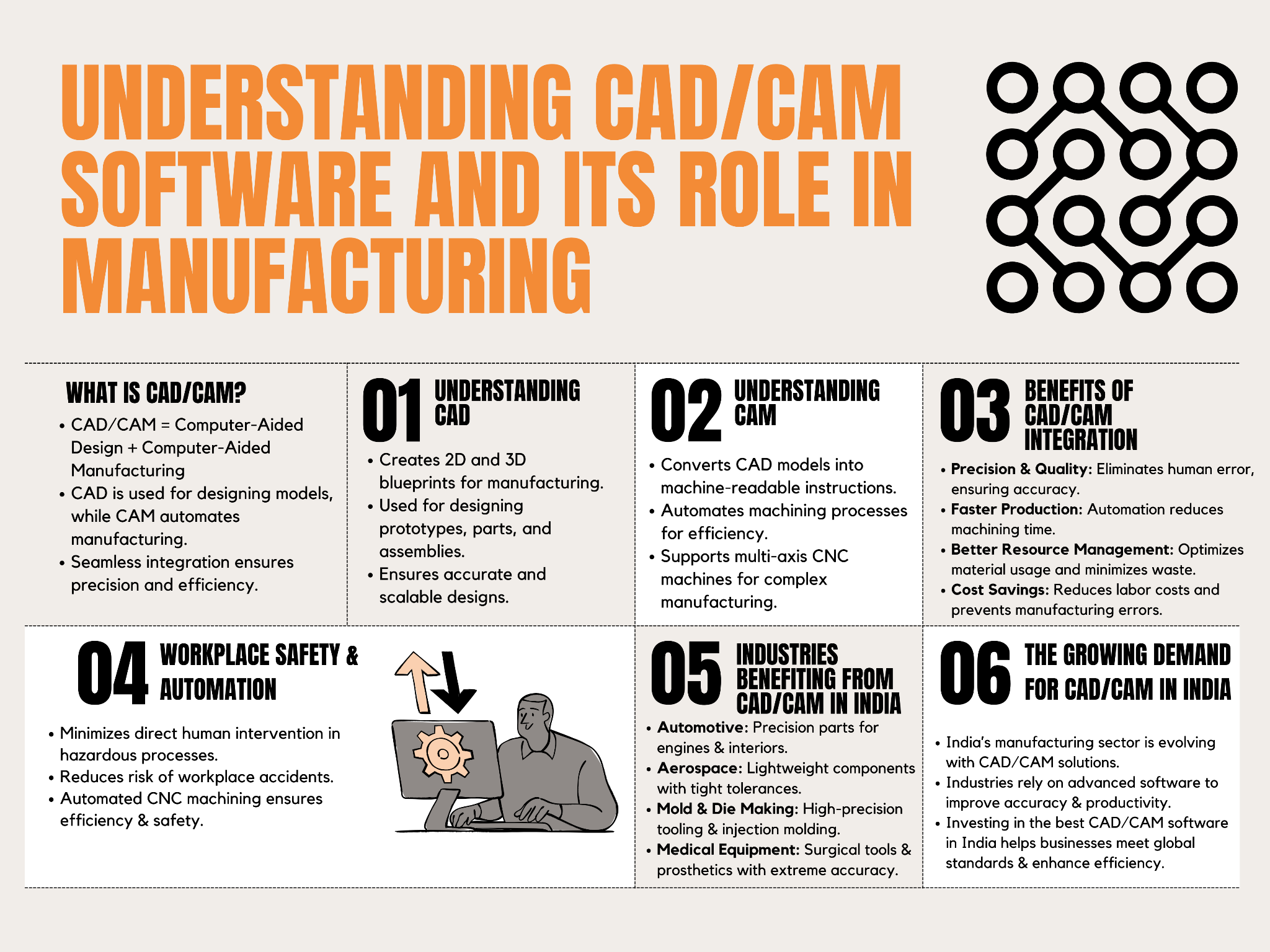

The combination of computer-aided design (CAD) with computer-aided manufacturing (CAM) is known as CAD/CAM. Prototypes, final goods, and production runs are all designed and manufactured with CAD/CAM software as a single development tool. This technology is essential to the automotive, aerospace, mold and die, and precision machining sectors. For industries seeking precision and efficiency, choosing the best CAD/CAM software in India is crucial for staying competitive in today’s market.

Understanding CAD/CAM Software and Its Role in Manufacturing

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) are the two terms that make up CAD-CAM. CAD software is used to create models and assemblies in a digital environment, and CAM software is used to automate manufacturing.

- Computer-Aided Design (CAD) is responsible for producing 2D and 3D models and blueprints that will subsequently be constructed.

- Computer-Aided Manufacturing (CAM) transforms CAD designs into machine-readable instructions, allowing for accurate and automated manufacturing.

Key Benefits of CAD/CAM Integration

- Precision and Quality: It guarantees high-accuracy components and removes human error.

- Enhanced Productivity: Automation increases efficiency and speeds up manufacturing.

- Resource Optimization: Helps to promote sustainability by reducing material waste.

- Workplace Safety: Reduces direct human interaction with potentially dangerous processes.

- Cost Savings: Production is automated, which lowers labor expenses and errors.

Growing Demand for High-Performance Machining Solutions in India

The manufacturing sector in India is undergoing a transformation thanks to CAD-CAM machining. In order to increase accuracy, productivity, and sustainability, industries including mold making, automotive, and aviation are depending more and more on advanced machining solutions. Investing in the best CAD/CAM software in India helps manufacturers meet global quality standards and improve production efficiency.

PowerMill: The Ultimate Solution for Advanced CNC Machining

Autodesk created PowerMill, a sophisticated CAM software designed for intricate and fast CNC programming. It is intended to generate toolpaths for CNC machines with three, four, and five axes. Manufacturers can streamline machining processes and attain unmatched precision by utilizing PowerMill.

Key Features of PowerMill

- Advanced Toolpath Strategies: Seamless transitions, high-efficiency machining, roughing, and finishing.

- High-Speed Machining Capabilities: Enhances surface finish while reducing cycle time.

- Collision Detection and Simulation: Safety and accuracy in manufacturing are ensured by collision detection and simulation.

- Support for Multiple Axes: Suitable for 3-, 4-, and 5-axis machining.

- Tool Database Management: Saves recurring project settings and simplifies tool selection.

Why PowerMill Stands Out

- Preferred option for producers of molds and dies.

- High compatibility with CNC machines that have multiple axes.

- Seamless integration with CAD programs such as Inventor and Autodesk Fusion 360.

Real-World Applications of PowerMill

- Aerospace: For producing robust, lightweight parts with precise tolerances.

- Automotive: Machining complex components for interiors, engines, and transmissions.

- Mold and Die Manufacturing: Extremely accurate molds for injection molding.

- Medical Equipment: Highly accurate machining of surgical instruments and implants.

FeatureCAM – Intelligent Automation for CNC Programming

A CAD/CAM application developed by Autodesk, FeatureCAM was created to automate CNC programming. It is perfect for precision machining because it automates feature recognition and optimizes toolpath generation, which speeds up manufacturing.

Key Features of FeatureCAM

- Automated Feature Recognition: Reduces programming effort and human error.

- Multi-Axis Support: Compatible with 3-, 4-, and 5-axis machining.

- Adaptive Roughing Techniques: Enhanced machining and quicker material removal.

- EDM Capabilities for Turning, Milling, and Wire: Versatile solutions for a range of manufacturing requirements.

Advantages of Using FeatureCAM in Indian Manufacturing

- Reduces errors in manual programming.

- Improves production efficiency through intelligent automation.

- Ideal for small- to medium-sized machine shops looking to increase efficiency.

Why PowerMill and FeatureCAM Are the Best CAD CAM Software in India

Adaptability and Personalization

With their incredibly flexible solutions, PowerMill and FeatureCAM serve a variety of industries, including tool & die, medical devices, automotive, and aerospace.

High Accuracy and Effectiveness

- PowerMill maintains exceptional machining precision while reducing cycle time.

- CNC programming is automated by FeatureCAM to improve consistency and efficiency.

Seamless Integration

Both software solutions ensure seamless operation by integrating easily with a variety of CAD platforms and CNC machines.

Cost-Effective Solutions

Indian manufacturers can reduce machining costs without sacrificing quality by using these software solutions. Many businesses searching for the best CAD/CAM software in India prefer PowerMill and FeatureCAM due to their cost-efficiency and advanced features.

| Aspect | PowerMill | FeatureCAM |

|---|---|---|

| Primary Focus | Advanced milling, especially for complex 3D and 5-axis machining | Feature-based automation for 2.5D, 3D, turning, and multi-axis machining |

| Target Users | Manufacturers needing high-precision, complex milling (e.g., molds, dies) | General machinists with a mix of milling, turning, and repetitive tasks |

| Automation Level | Lower; focuses on manual control and flexibility for complex toolpaths | Higher; uses feature recognition and automation for faster programming |

| Axis Support | Strong emphasis on 3-axis, 5-axis, and multi-axis machining | Supports 2.5-axis, 3-axis, 4-axis, 5-axis, and mill-turn operations |

| Ease of Use | Steeper learning curve due to advanced features and customization | More user-friendly with automated workflows and a simpler interface |

| Key Strength | Exceptional for complex 3D surfaces, 5-axis strategies, and toolpath editing | Speed and efficiency in programming standard parts and repetitive jobs |

| Turning Capabilities | Limited; primarily milling-focused | Strong; includes robust turning and mill-turn support |

| Toolpath Flexibility | Highly customizable toolpaths with detailed control | Less flexible; relies on predefined strategies and feature-based workflows |

| Simulation | Advanced simulation with collision detection and machine kinematics | Good simulation, but less detailed than PowerMill for complex scenarios |

| Ideal Applications | Aerospace, automotive molds, intricate 5-axis parts | Production machining, simpler 3D parts, turning, and multi-tasking |

| Integration | Works standalone or with Fusion 360 (as Fusion 360 with PowerMill) | Bundled with Fusion 360 (as Fusion 360 with FeatureCAM) |

| Cost | Generally higher due to advanced capabilities | More affordable, especially for small-to-medium shops |

How Mechman Solution Supports Your CAD/CAM Needs

Mechman Solution is a reputable Autodesk software provider that offers tailored solutions to increase manufacturing productivity.

Consulting and Software Implementation

- Assisting companies in selecting the best CAD/CAM software for their specific requirements.

Training Programs

- Providing users with practical instruction to help them maximize the software’s capabilities.

Technical Assistance and Maintenance

- Offer maintenance services and troubleshooting support to ensure seamless software performance.

Customization and Process Optimization

- Developing customized solutions to address production challenges unique to a given industry.

Key Takeaway

Among the best CAD/CAM software in India, PowerMill and FeatureCAM provide manufacturers with accuracy, productivity, and automation. They are perfect for the mold & die, automotive, and aerospace industries due to their advanced capabilities.

To improve your manufacturing capabilities, contact Mechman Solution today for a training session, consultation, or demo!